Disc Bowl Centrifuge

28 มีนาคม 2566

ผู้ชม 441 ผู้ชม

SUMMARY

A supporting framework intended for bench mounting houses the separator, complete with its variable speed drive control unit, food reservoir and the necessary ancilliary equipment.

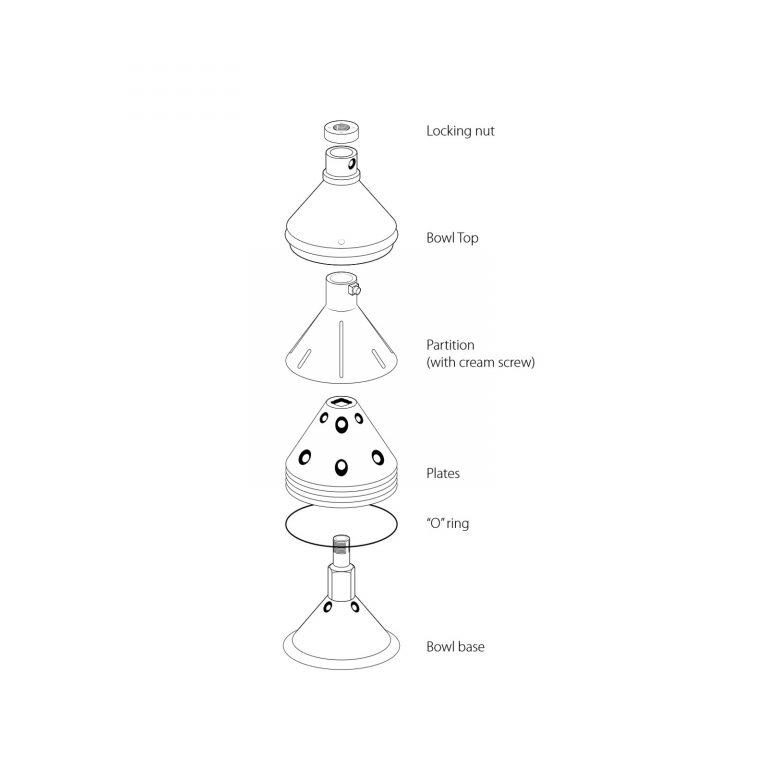

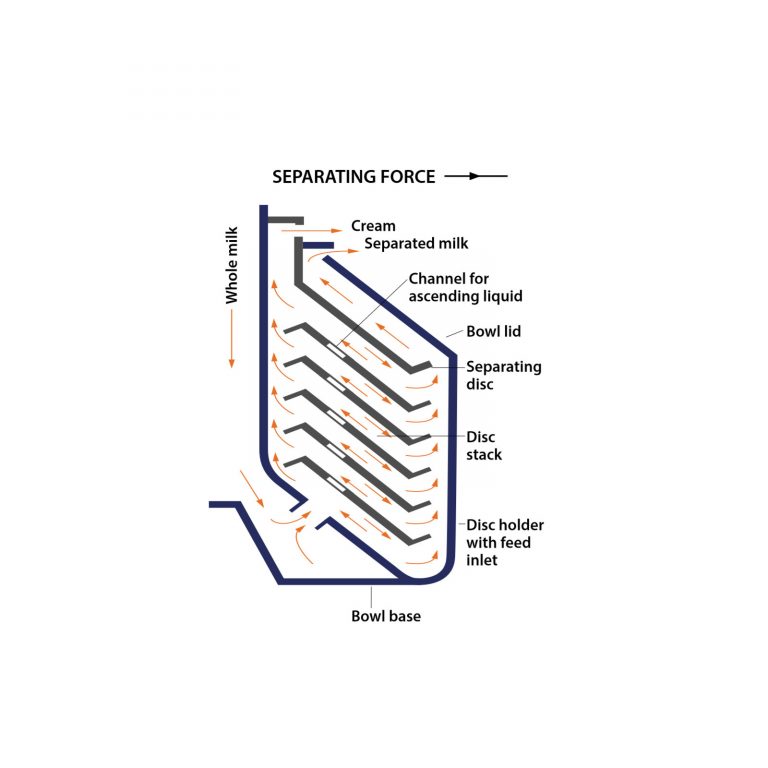

The feed reservoir, positioned over the centrifuge, is made from grey anodised aluminium and contains a polypropylene on/off valve. The separator bowl assembly is made up of stainless steel disks and an anodised aluminium casing with nitrile rubber sealing ring, housed in a polypropylene shroud which incorporates the cream and skimmed milk outlets.

A motor, directly coupled to the separator bowl, is mounted vertically in a cast aluminium casing with cushioned clamping feet. The casing acts as the support for the separator.

Ancillary equipment to facilitate a thorough investigation into this type of separation consists of:

- Optical tachometer

- Product collecting vessels

- Stop clock

- Tools

The backboard includes a sectioned diagram detailing the component parts of the separator bowl and describing its mode of operation.

FEATURES & BENEFITS

The centrifuge provides practical instruction exercises in all aspects of cream/milk separation including:

- Production of a variety of creams having milk fat contents from 12%-55%

- Demonstration of the effect of temperature and bowl speed on separator performance

- Demonstration of the effect of product type on throughput

- Learning the importance of cleanliness and hygiene in food processing

- Understanding the mode of operation of this type of centrifuge, using instructive diagrams and ease of stripdown to component parts

ADDITIONAL INFORMATION

| Weight | 60 kg |

|---|---|

| Dimensions | .6 × .6 × .4 m |

TECHNICAL SPECIFICATIONS

- A self-contained centrifugal separator training unit which allows thorough investigation of the separation of a heavy phase liquid from a lighter phase liquid

- Using milk as the process fluid, cream having a fat content from 12-55% can

be obtained. Accessories are included to allow variation and measurement of bowl speed and throughput rate measurement. Ease of stripdown to component parts is facilitated by tools included in the supply - Throughput up to 125 l/hr can be obtained from a 10l capacity feed tank, which can be continuously replenished

- Materials in contact with the process fluid are anodised aluminium, stainless steel, nitrile rubber and polypropylene

- 12 motor speeds between 8,500 and 10,000rpm are selectable

- Accessories mounted on the framework include:

– Optical tachometer

– Stop clock

– Product collecting vessels

– Tools - A comprehensive instruction manual is included in the supply detailing installation, commissioning and operation

- Separator bowl incorporates 19 discs

- 12 motor speeds between 8,500 and 10,000rpm are selectable by switch on the motor control housing

- The tachometer has a five-digit display and a measuring range of 60-19,999rpm

- Resolution 1 rpm

- Two graduated sample collecting vessels, glass, 1.0l and 0.4l

- One stop clock, 100mm dial, 30-hour spring driven movement with start/stop and reset push buttons