Laboratory Pasteuriser

หมวดหมู่สินค้า: INDUSTRIAL FOOD TECHNOLOGY

รหัส : FT43

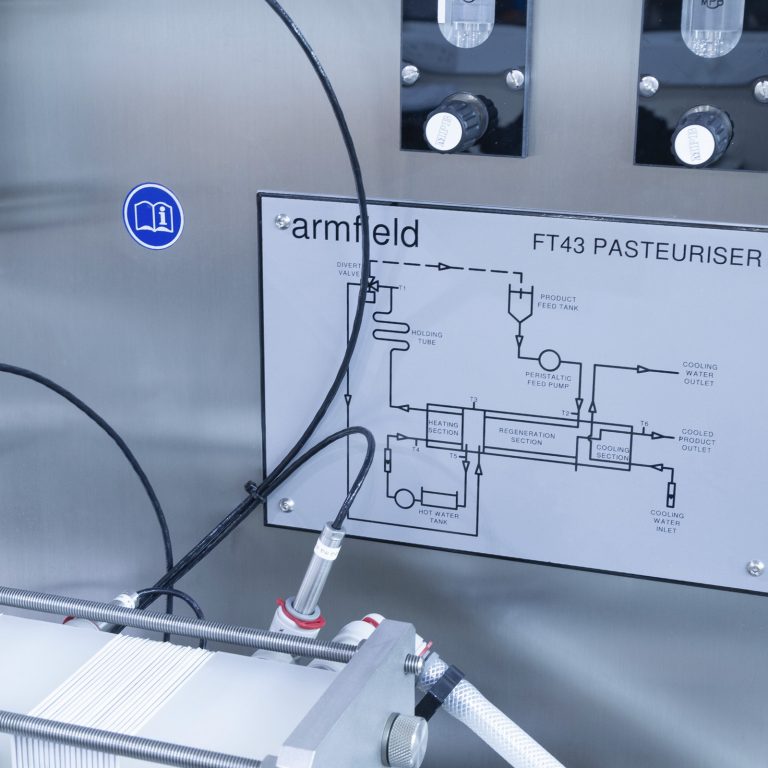

This self-contained laboratory unit is suitable for HTST (high temperature, short time) pasteurisation of up to 20 litres/hour of a wide variety of low-viscosity liquid foods. Products that may be pasteurised include raw milk, nectars, fruit juices, skimmed milk, ice-cream mix, soft drinks, pharmaceuticals and margarine emulsion.

28 มีนาคม 2566

ผู้ชม 145 ผู้ชม

SUMMARY

This self-contained laboratory unit is suitable for HTST (high temperature, short time) pasteurisation of up to 20 litres/hour of a wide variety of low-viscosity liquid foods. Products that may be pasteurised include raw milk, nectars, fruit juices, skimmed milk, ice-cream mix, soft drinks, pharmaceuticals and margarine emulsion.

A CIP (clean-in-place) facility is incorporated which allows disinfection, pre-rinsing, detergent washing and final rinsing. The ability to vary process conditions has been built into the unit in the form of the following features:

- Variable speed, peristaltic, hygienic feed pump allowing flow rate variations

- Plate-type stainless steel heat exchanger – the cooling, regenerating and heating sections, mounted on a common frame work, are easily dismantled to allow re-configuration and inspection of the heat transfer surfaces

- Electrically heated hot water circulating system for both pasteurisation and CIP cycles – any required holding tube outlet temperature is set on the indicating microprocessor-based power output controller of the water heater

- Stainless steel holding tube, allowing holding times between five seconds and two minutes

- Flow rates of feed pump, cooling water and hot water are monitored accurately

- Temperatures in the system are monitored with thermocouple sensors at each of six chosen locations (nine available)

- Maximum process temperature 85°C

FEATURES & BENEFITS

BENEFITS

- Tests can be carried out quickly and easily

- Simulates the conditions used in a production plant

- Small quantities of liquid product can be processed

FEATURES

- Miniature plate heat exchanger

- Fully self-contained design with integral hot water system

- Choice of holding tubes

- Variable product temperature and holding time

- Control console incorporating comprehensive instrumentation

- CIP facility benchtop operation

TECHNICAL SPECIFICATIONS

Optional 15-second holding tube included in supply

More.