HTST/UHT Mini Pilot System

28 มีนาคม 2566

ผู้ชม 258 ผู้ชม

SUMMARY

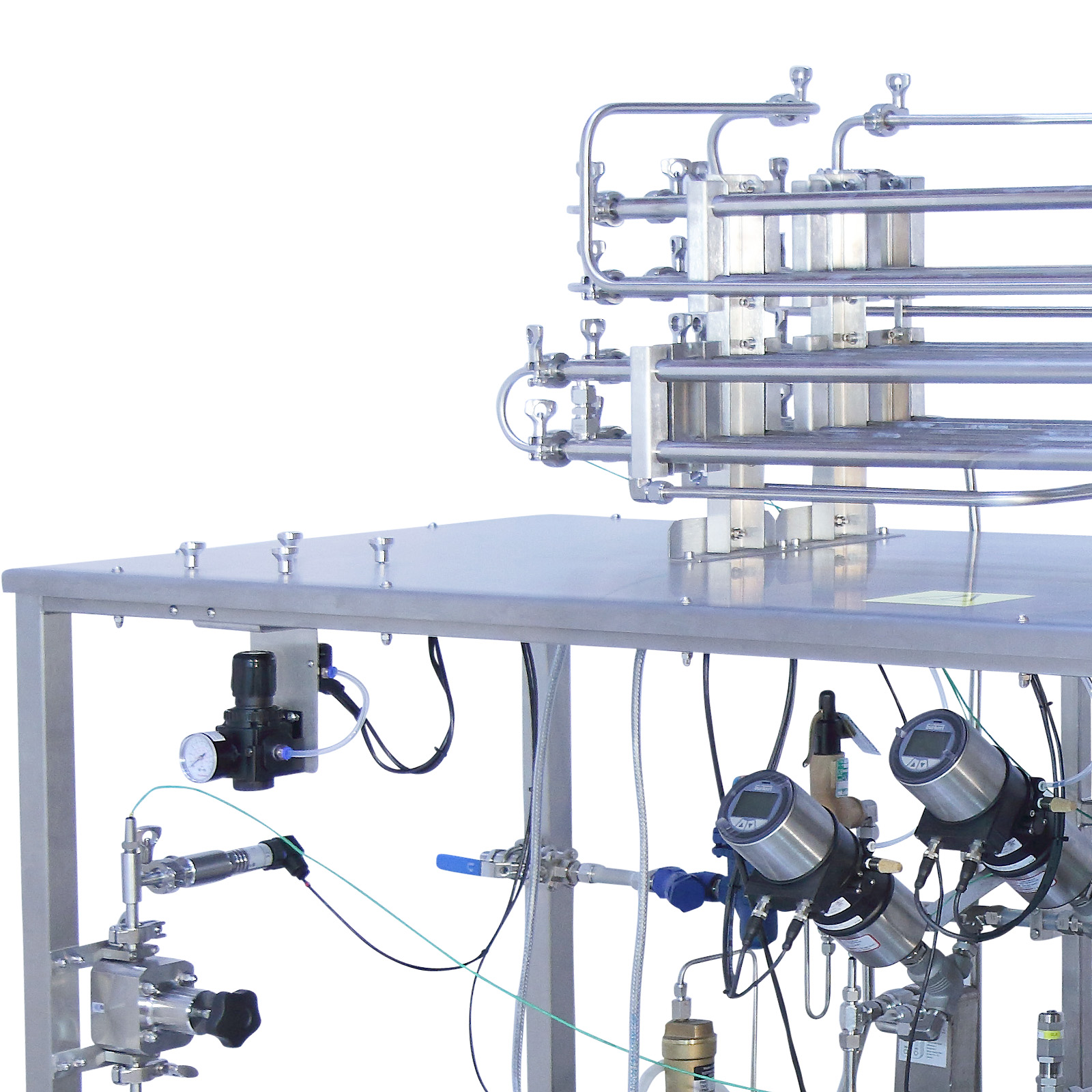

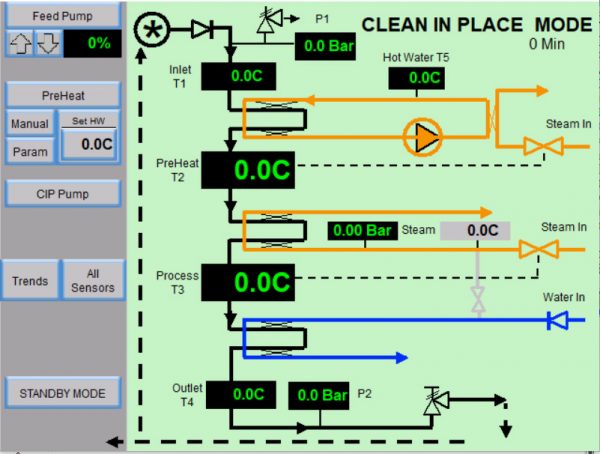

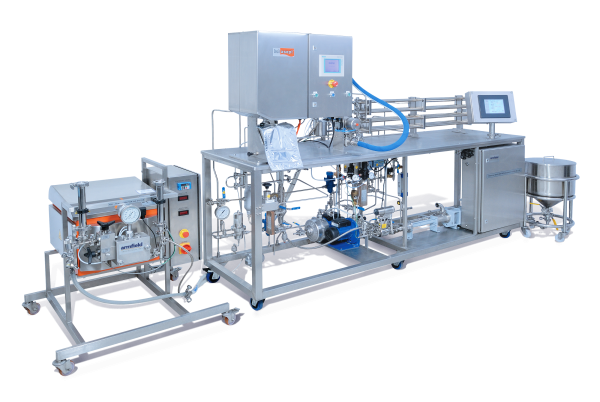

The FT94X service unit contains the services, controls and instrumentation required to operate the tubular and plate heat exchangers described below. The FT94X may be specified with either or both of the heat exchangers. Switching between the two heat exchangers takes a matter of seconds.

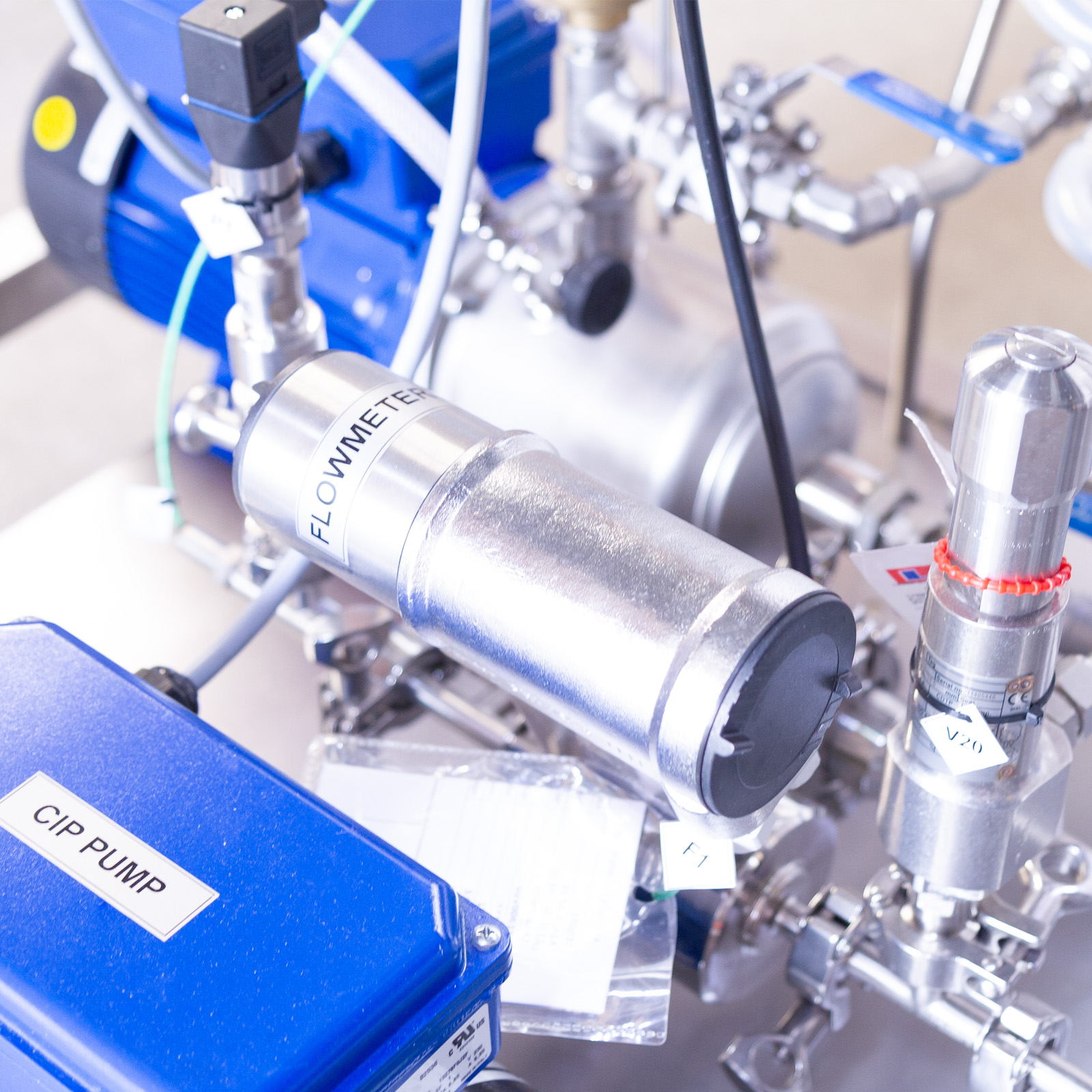

The service unit comprises: an eight inch touch screen control panel with the required controls and displays; a variable speed progressive cavity product feed pump with inlet level sensor and alarm to warn of low product level; a steam-heated hot water system for product preheating; automatic steam control valves for product preheating and final heating; a centrifugal CIP pump and other facilities required for CIP and SIP.

Sensors show product inlet, preheat, final heating and outlet temperatures. Product preheat and final heating temperatures are set by the operator. Inlet and outlet product pressure is also shown. There are various service sensors: pressure, level and temperature – see process flow diagram for details.

A sophisticated data logging package enables the measured data to be recorded onto a standard Windows PC (not supplied). The software records all temperatures, product and steam pressures, feed pump speed and many other sensor values. Data from optional accessories (e.g. the flowmeter) is also recorded. Data may be displayed in tables and graphs (both real time and comparisons across previous runs), and may also be exported to MS Excel.

Interface: USB Software requirements: Win 98, ME, 2000, XP, Win 7/8/10

FEATURES & BENEFITS

- Compact design and easy installation

- Low product hold up

- Suitable for producing large batches of material for extensive product testing

- Suitable for a wide range of products due to both plate and tubular exchangers

- From cold start to steady state operation in seconds

- Rapid switchover from one heat exchanger to another

- Designed for easy integration into a process line

- Links directly to sterile filling bench or sealed bag filling systems

- Touch screen control for ease of use

- Compact, mobile, easy to install

- Continuous and batch operation

- Standard throughputs from 30 to >100 l/hr (dependent on conditions)

- Units available to 200 l/hr

- Process temperatures up to 150°C

- Capable of aseptic operation

- Fully instrumented

- Preheating by hot water (indirect)

- Heating by steam (indirect)

- Plate and tubular heat exchanger options

- Controlled product preheat and heating temperatures

- Simple and rapid switch over between heat exchangers

- Automatic product divert for low temperature on tubular heat exchanger

- Built in Clean In Place (CIP) and Sterilisation In Place (SIP) facilities

- Integral USB data logging

- Two-stage cooling option

- Electronic flowmeter option

- Suction feed with in-line level sensor

Applications

- Baby foods

- Beer

- Condiments

- Confectionery

- Culture media

- Desserts and puddings

- Fruit and vegetable purees

- Health and nutritional products

- Fruit juices and cordials

- Gelatine products

- Gravies

- Cream

- Ice cream

- Sauces and soups

- Yoghurts

- Meat pie fillings

- Milk

- Pet food

- Pharmaceuticals

- Ready meals

TECHNICAL SPECIFICATIONS

FEED PUMP

Progressive cavity variable speed pump

Solids handling: Soft 10 mm

Solids handling: Hard 4 mm

Flow rate: 30-100 l/hr

Discharge pressure: 24 bar (max)

PRE-HEAT WATER SYSTEM

Water capacity: ~2-3 litres

Maximum temp: 110°C

Safety cut-outs: Low level

Safety cut-outs: Temperature

Safety cut-outs: Product pump

Safety cut-outs: Pressure relief valve

HEATING SYSTEM

External steam supply

Maximum temp: 165°C

Maximum temp: Relief valve (7 barg)

Maximum temp: Product pump off

Maximum temp: steam valve closes

Max product heating duty: 17kW

Maximum temp: (preheat + heating)

TUBULAR HEAT EXCHANGER (FT94-20)

Number of tubes 10 (2 preheat, 4 heating, 4 cooling)

TUBE DIAMETER

(product side): 8.1 mm

Overall diameter: 22.0 mm

Length (heated): 1.46 m

Product volume: 1.0 l

Material: 316 stainless steel

Assembled test pressure: 30 bar

Working pressure: 24 bar (maximum)

PLATE HEAT EXCHANGER (FT94-30)

Plate overall dimensions: 150 x 480mm

Effective area per plate: 0.04m²

Plate thickness: 0.6mm

Product volume: 2.5litres

Plate Material: 316 stainless steel

Gasket Material: Food grade Viton

Max differential test pressure: 11.5bar

Max balanced test pressure: 12.5bar

Max working pressure: 9.6bar

Working temperature Max: 1/0°C

Min: -4°C

NUMBER OF PLATES

FT94-30 Preheating 13, Heating 6, Cooling 13

FT94-33 Secondary cooling 7