เครื่องทดสอบแรงดันขวด (Bottle Pressure Tester)

27 ธันวาคม 2567

ผู้ชม 706 ผู้ชม

SUMMARY

CanNeed-PEBT-4000 PET Bottle Pressure Tester is advanced testing equipment specialized for testing the PET bottles. It has been designed in conformity to the three international commonly used testing methods. CanNeed-PEBT-4000 is able to test the pressure capabilities that under a set pressure or the burst test in order to check whether the PET bottle is qualified to meet the requirement of the packaging industry.

By the means of water replenishing pressurization, the pressurizing process was linearized and increased until reaching the preset point or burst point.

Users can select the testing mode through the touch-screen. Fill the sample, close the protection door, then press start. When the testing starts, the PEBT-4000 will clamp the sample and run according with the settings automatically. The touch-screen will display the real-time pressure value and record down the max. pressure (passing test) and burst pressure (destructive test).

FEATURE.

- PEBT-4000 PET Bottle Pressure Tester (Burst Tester) is the standard equipment for PET bottle industry.

- Three (3) international commonly used testing methods.

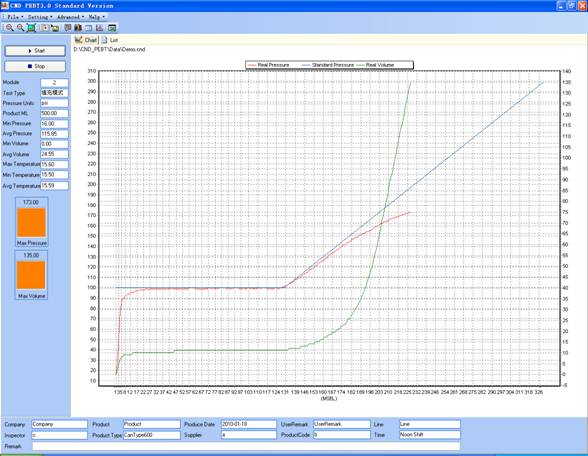

- CND-PEBT Professional software.

- Preset testing mode and user-defined mode.

- Display the curve of pressure and volume expansion during the test.

- Monitor and record the water temperature during the test.

- Applicable for different size of plastic bottles.

- Touch-screen contolled.

- RS232C data output.

- With calibration function, convenience for calibrating

Three (3) international commonly used testing methods.

Fill Ramp mode:

The fill ramp mode was designed to simulate the situation of PET bottle filling lines. In this mode, PET bottles will be pressurized rapidly to the preset initial pressure and hold for 13 seconds. Then continue to pressurize with a speed of 10 pound/inch2 (0.69kg/cm2) until the bottle burst or reaches the max. pressure or volume. Preset parameters include: preset initial pressure, max. pressure and volume expansion limit.

Burst mode:

In this mode, PET bottles will be pressurized rapidly to the preset pressure value and hold for a period as preset. Preset parameters include: burst pressure, testing time and volume expansion limit.

User-defined mode:

The User-defined mode of PEBT-4000 is able to create the unique pressurizing curve to meet the special testing requirements. Users can set the pressurizing curve by stages, after the setting is done, the corresponding curve will display on the user interface.

PEBT-4000 is the standard equipment for PET bottle industry, it can help to improve the PET bottle performance

PEBT-4000 is a standard equipment for testing the PET bottle performance. The PET bottle volume expansion is related to many key PET bottle performance factors, those factors including creep, gas permeation, burst, stress cracks, rigidity, bottom roll-out, topload (axial load), and thermal stability.

The Advanced CND-PEBT professional software

Use the CND-PEBT professional software to build up the communication of PEBT-4000 and computer, the software can save and manage the testing data, display the real-time curve of pressure and volume expansion, monitor and record the water temperature during the testing process.

User-friendly Operating Interface

PEBT-4000 adopted the touch-screen for all the controlling operation and testing data displaying.

Features of User Interface:

- Simple and convenient operating

- Touch-screen controlled

- Graph displaying of the testing curve

- Comprehensive report data after tests

APPLICATION.

Beverage Industry

SPECIFICATION.

| Technical Points | Description |

| Operating Pressure Range | 0-300 Psi (0-20.7 bars) |

| Accuracy | ±3 Psi (±0.2 bar) |

| Pressure Units of Measure | Psi, kg/cm2, bars, MPa (user defined) |

| Volume Expansion units of Measure | Milliliters(ml) |

| Pressure Source | Recommended to use Nitrogen gas (not supplied) |

| Water Source | 0.1 - 0.3 MPa tap water |

| Operating Temperature | 0-50℃ |

| Power Supply | 110-120 or 220/240VAC @ 50/60 Hz |

| Expansion Capability | 2 L |

| Bottle Sizes Supported | Up to 3L (depending on expansion percentage) |

| Output Interface | Standard serial link |

| Dimensions | 830×580×1600 mm (W × D × H) |

| Weight : | 120KG |