เครื่องมือจำลองการผลิตเครื่องดื่มอัดก๊าซ พร้อมระบบเติมตัวอย่างและปิดผนึกผลิตภัณฑ์แบบอัตโมัติ (Carbonator, Filler & Capping)

28 มีนาคม 2566

ผู้ชม 3305 ผู้ชม

SUMMARY

The Armfield FT102XA miniature-scale carbonator provides the ability to establish precise and repeatable parameters when carbonating in the laboratory, this can dramatically improve the speed with which new products are developed.

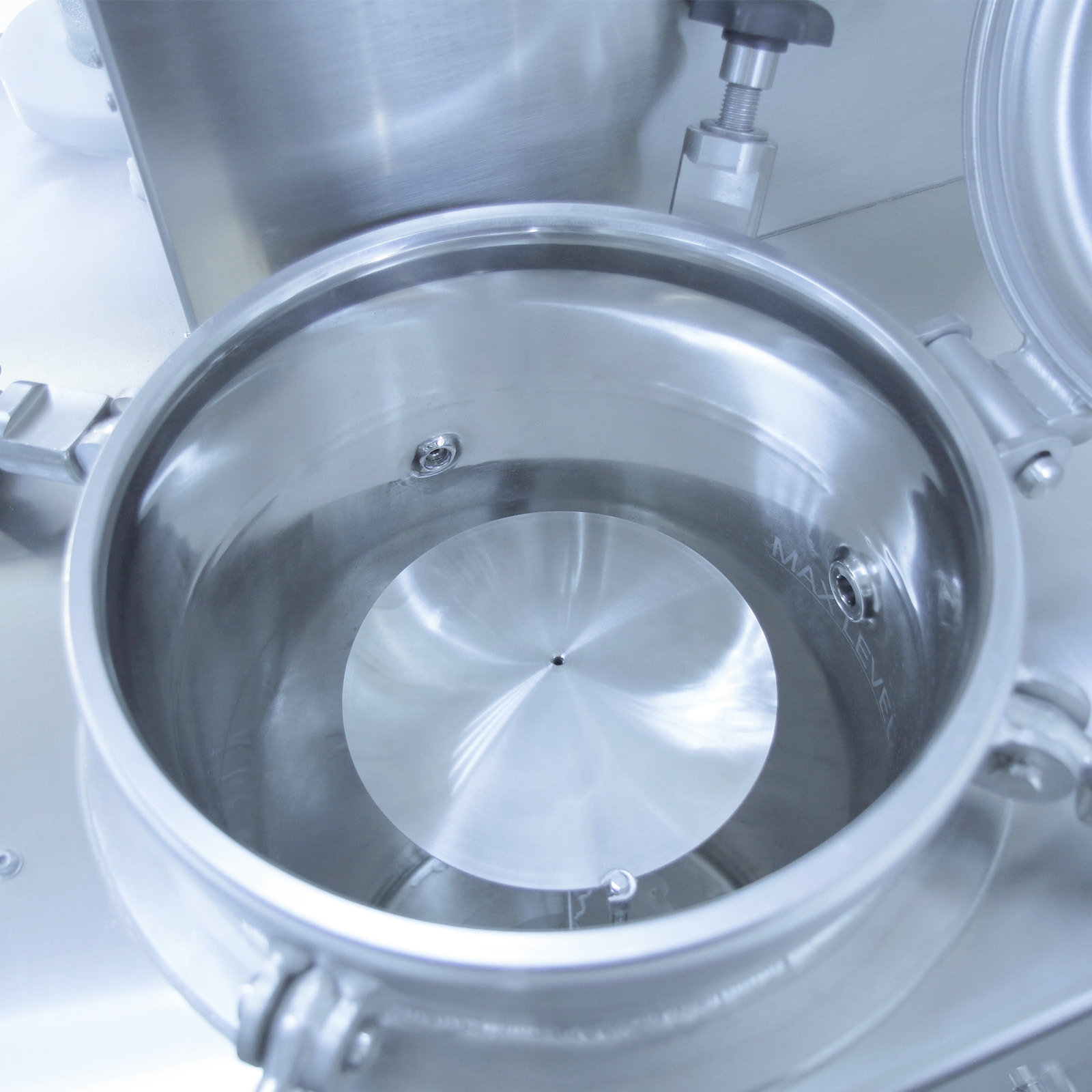

The FT102XA is a totally new design including a large number of improvements and enhancements. In particular, special attention has been given to the ease of use, enhanced flexibility, reliability and improved Clean In Place (CIP).

Both premix and postmix operations are available from the standard machine, and an option is available to add the syrup for postmix automatically. Other options enable for deaeration of the product and evacuation of the bottles, continuous processing capability, and filling and capping (screw and/or crown) at a single station without removing the bottle.

The FT102XA Carbonator, Filler is easy to install, set up and use.

Colour touch screen control is used with a new graphical interface, enabling different carbonating and filling scenarios to be set and stored. The improved semi-automated cleaning program takes the user step by step through the cleaning process and enables the unit to be made ready for another product or formulation.

FEATURES

1. Accurate carbonation levels in excess of 12g/l (± 0.1g/l)

2. Cans, PET and glass bottle filling

3. Screw, crown, rip-cap and ROPP capping

4. Can seaming

5. CO2 recycling for environmentally friendly processing

6. Deaeration

7. Vessel purging

8. New vacuum system compatible with high foaming products

9. In-bottle pressure measurement

10. Pre-mixing and post-mixing capability

11. Syrup dosing into the bottle

12. ArmBUS control system with 32 process recipes and flexibility of computer control over PLC control

13. Full data capture through ArmBUS data viewer (exportable to Excel)

14. Twin filling head option available

BENEFITS

1. Reduced movement of bottle increases the accuracy and reliability of carbonation

2. On-board high-efficiency chiller reduces space required in laboratory

3. Removable side panels and IP65 electrical cabinet for easy access to internal components and spray down when required

4. Can operate as standalone unit or with the continuous feed vessel FT102XA-44

5. No need for an external chiller or ice water supply

APPLICATION

The FT102XA is ideally suited as a general purpose filling and carbonation installation for small laboratory applications. Used in conjunction with one of Armfield’s FT74XA UHT/HTST units, a complete drinks line can be created in the laboratory; consisting of heat treatment, carbonation, filling and capping.

TECHNICAL SPECIFICATIONS

Gas content: 0-12 g/l.

Vessel capacity: 15 liters or 30 liters working capacity.

Capping Methods: Screw, Crown, Can Lid, ROPP, Rip-Cap.

Gases: CO₂ , N₂ or any safe, non-flammable alternatives or mixture.

Contact surfaces: 316L stainless steel, food-grade silicone, PTFE, borosilicate glass and other food safe materials.

Operation methods: Batch or Semi-continuous.

Minimum batch volume: 1 – 3 liters (depending on vessel volume).

Maximum vessel pressure: 4 bar.