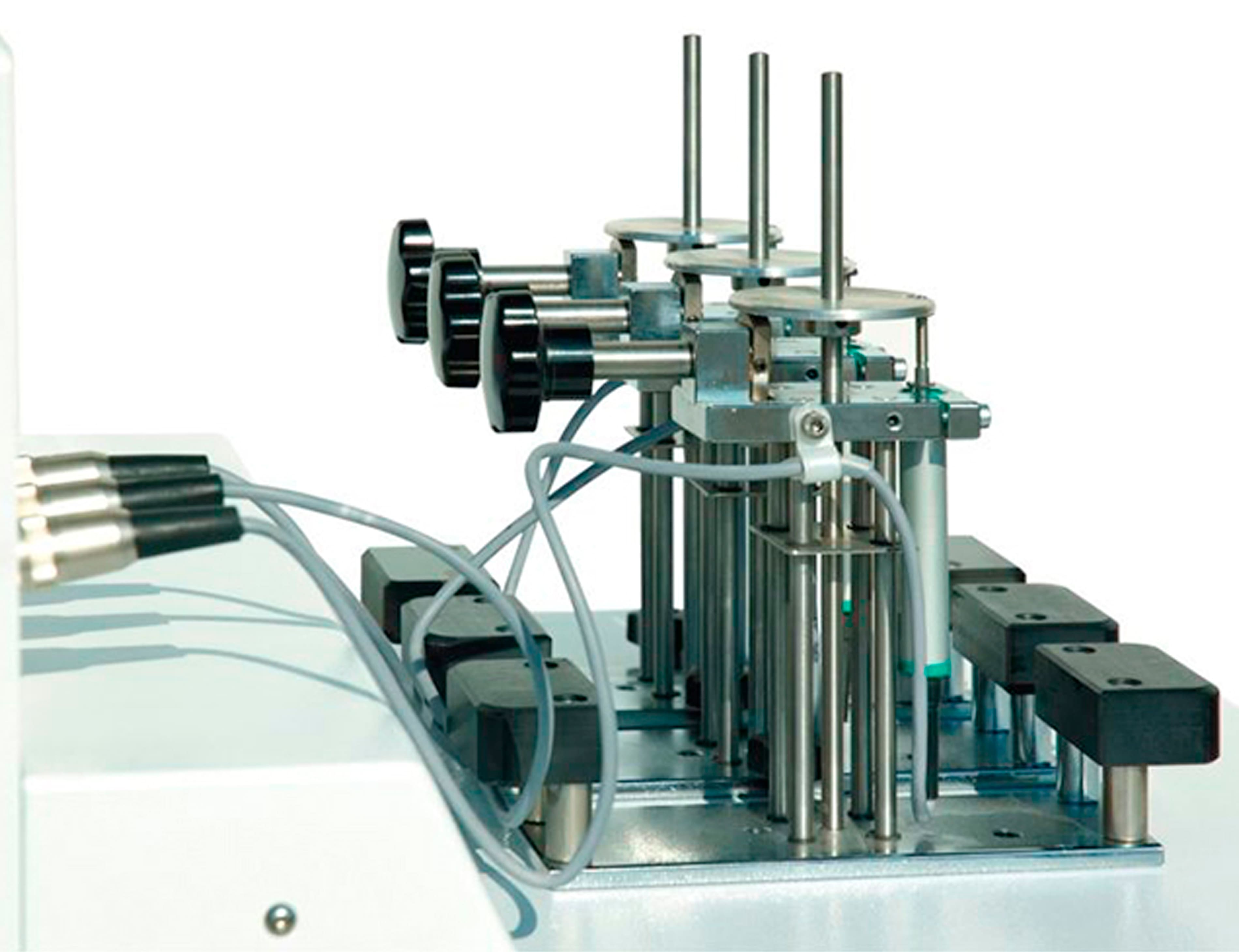

HDT-VICAT MP3 / MP6 (3 & 6 Stations)

31 มกราคม 2568

ผู้ชม 20 ผู้ชม

HDT-VICAT MP3 / MP6 (3 & 6 Stations)

Cod: 380207 / 380208

Standard: ASTM D1525, ASTM D648, DIN 53460, DIN 53461, ISO 306, ISO 75-1, ISO 75-2.

Equipment to determine the bending temperature (Heat Deflection Temperature) and the softening temperature (Vicat) of thermoplastic materials.

Both 3 and 6 station apparatus determine the temperature at which a standard hammer shaped head, with a load calculated to obtain a known stress, deflects at a conventional value a specimen during an incremental linear temperature gradient (HDT: Heat Deflection Temperature) and the temperature at which a standard needle, under a known load, penetrates of 1± 0.01 mm the surface of a specimen during an incremental linear temperature gradient (VICAT).

Measuring the resistance to the deflection temperature is very important for the characterization of products, for the Quality Control process and to evaluate the product conformity to the required standards.

FEATURES:

-

- Steel structure painted with epoxy resin

- Compact stainless steel inner oil bath with volume designed to guarantee a perfect heat exchange even with lower heating and cooling times

- Working temperature: from ambient to 300°C.

- Testing stations equipped with a patented system to perform tests with a maximum error of 0.01 mm.

- Temperature uniformity: ±0.2°C on all the volume bath, by means of stirring and circulation system of the diathermic liquid.

- Cooling by means of forced water circulation inside a cooling jacket, offering a quicker cooling than traditional coils. The system prevents the risk of pollution of the diathermic liquid.

- Typical recovery time from 200°C to 30°C, with cooling water at 18°C, taker about 30 minutes, due to the bath and the cooling jacket dimension.

3 ESTATION MODEL INCLUDING:

• Microprocessor, Touch Screen TFT colour

• 3 HDT heads (one for each station)

• 1 centring tool for HDT heads

• 3 series of 12 weights for HDT tests (1-2-4-8-16-32-64-128-256-512-1024-2048 g with binary increase) to obtain 455 or 1820 kPa

• 3 Vicat heads (one for each station)

• 3 series of 2 weights for Vicat tests (910-4000 g) to obtain 9,85 or 49,5 N

• Volume of the bath: 8 litres

• Cooling water inlet/outlet system complete with filter

• Tap for oil discharge

6 ESTATION MODEL INCLUDING:

• Microprocessor, Touch Screen colour 7”

• 6 HDT heads (one for each station)

• 1 centring tool for HDT heads

• 6 series of 12 weights for HDT tests (1-2-4-8-16-32-64-128-256-512-1024-2048 g each.) to obtain 455 or 1820 kPa

• 6 Vicat heads (one for each station)

• 6 series of 2 weights for Vicat tests (910-4000 g) to obtain 9,85 or 49,5 N

• Water supply group complete with filter

• Stainless steel tank cap. about 16 liters

• Tap for oil discharge