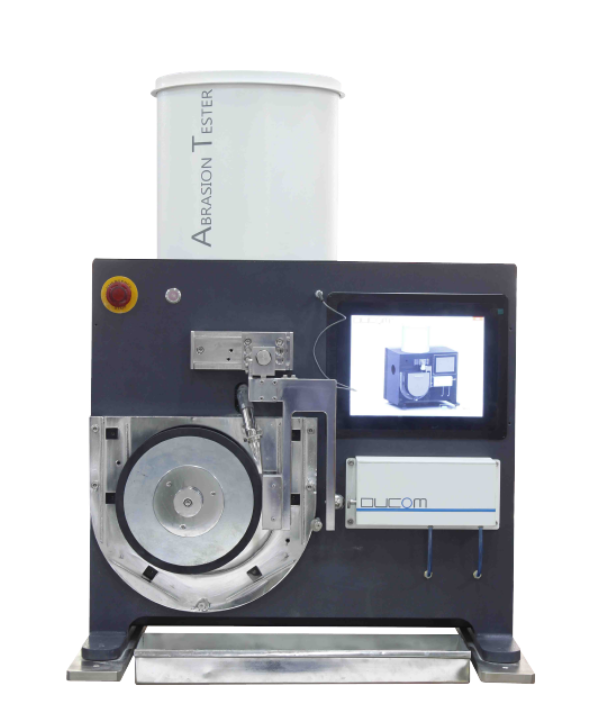

Desktop and Automatic

Measure wear friction under three body abrasion conditions.

ASTM G65 (dry abrasion), ASTM G105 and ASTM B611 (slurry abrasion) compliant.

Technical Specifications

- Load: 100 N to 300 N (automatic)

- Speed: Up to 250 rpm

- Friction Force: up to 300 N

- Duration 999,999 rev (Max)

Test Standards

- ASTM G65: Standard Test Method for Measuring Abrasion Using the Dry Sand/Rubber Wheel Apparatus.

- ASTM G105: Standard Test Method for Conducting Wet Sand/Rubber Wheel Abrasion Tests.

- ASTM B611: Standard Test Method for Determining the High Stress Abrasion Resistance of Hard Materials.

Application Examples

- Ranking of materials with respect to its abrasive resistance (dry and slurry).

- Quality analysis and product development of molding tools used in sand-lime bricks.

- Research in the area of refractory ceramics.

- Abrasive wear resistance of hard face coatings

Product Features

COMPACT AND MODULAR

Dry Sand Abrasion. Slurry Abrasion.

The ABT-3 abrasion tester can test samples in dry sand abrasion conditions and in slurry conditions. The carefully thought out design makes this transition easy and quick.

GET MORE DATA

Wear, friction data with each test

Built in instrumentation and data logging capabilities help you extract more information with each test. Automatic loading that can be controlled with the touch of a button and continuous friction data logging help in studying not only wear resistance but also the friction behavior of materials.

%20-%20Dry%20Abrasion%20Test%20GIF.gif)

AUTOMATION

Ease of use is central to our design

We instrumented our Abrasion Tester (ABT-3) so that setting up tests would be easy and require very little training. Our guided software and automatic loading capabilities make the system safer and more convenient than ever before.

%20-%20Automatic%20Loading%20System%20GIF.gif)

DATA ACQUSITION AND CONTROL

Touch screen interface and Industry 4.0 ready

The system comes standard with a touch screen interface and an easy and intuitive software. Every test is automatically logged and ready for reporting at your convenience.

The Abrasion Tester (ABT-3) is also compatible with MOOHA which enables access to instant instrument health monitoring, tamper proof test data, automatically maintains an audit log and more.