PFI MILL

04 สิงหาคม 2566

ผู้ชม 198 ผู้ชม

PFI MILL

For grinding pulp in laboratory quantities under standardized conditions (30 g).

DEVICE DESCRIPTION

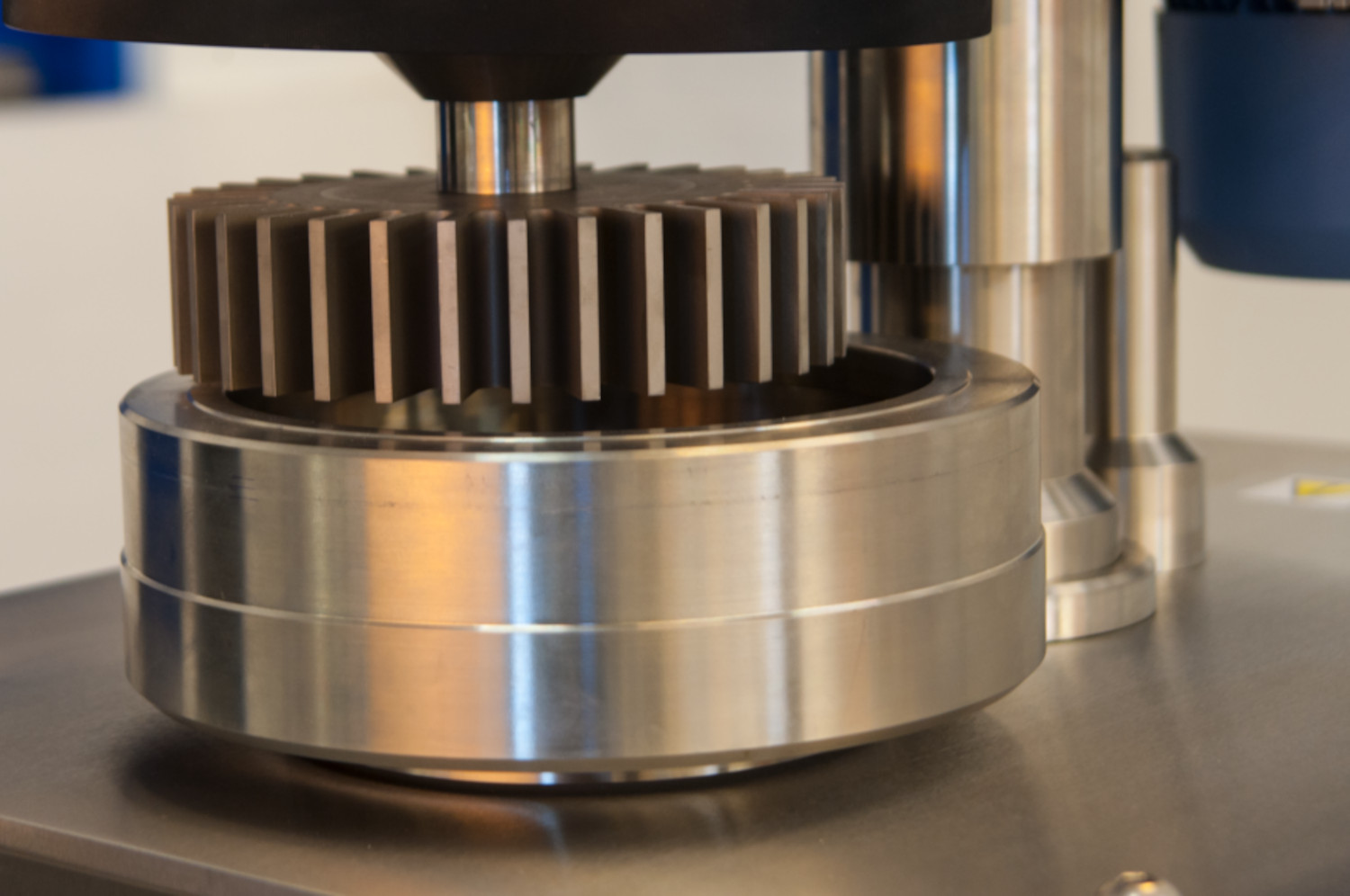

The PFI mill is used to grind cellulose samples on a laboratory scale. Correct grinding is the first important step in producing test sheets of the appropriate quality. The heart of the PFI mill consists of two rollers: an inner toothed roller (grinding body with 33 knives) and a smooth grinding sleeve. A cellulose sample that has been weighed and prepared with the standardized disintegration device (code: P.401.x) is placed in the grinding container and distributed evenly over the entire inner wall. Then the grinding media is lowered into the grinding sleeve. After pressing the start button, the rollers rotate at different speeds in the same direction and the grinding process starts. Due to the contact pressure of exactly 3.33 N/mm, the pulp is ground under constant standardized conditions. After the process, the grinding body stops automatically and returns to its inital position. Now the ground pulp can be taken to determine the Schopper-Riegler value (° SR) by means of a Schopper Riegler Freeness Tester (Code: P.403.xx). Then the device is available for further grinding and a grinding curve can be created.

FEATURES

-

grinding sleeve and grinding body made of robust stainless steel

-

toothed belt drive

-

automatic start after pressing a button

-

Beating of 24 – 30 g pulp with a concentration of 10% (max. 300 ml of suspension)

-

the grinding body stops automatically after the grinding process and moves back to the center of the grinding sleeve after the preset number of revolutions

-

adjustable grinding gap

-

cleaning opening at the bottom of the grinding jar for easy emptying

-

special device for cleaning the toothed roller

-

constant contact pressure (weights): no influence of compressed air fluctuations during grinding

-

digital display of operating hours

-

work performance in W (measurement constant)

-

milling energy in kWh during the milling process

APPLICABLE STANDARDS : ISO 5264-2; DIN-EN 25264-2; TAPPI T248; SCAN C24; PAPTAC C7

SPECIFICATIONS

| speed of the beater roll | 1 458 ± 30 rpm |

| speed of the beater housing | 700 rpm |

| beating force | 3.33 N/mm |

| grinding time | 2 - 10 minutes depending on the type of pulp |

CONNECTIONS

| Electricity | 400 V, 50 Hz AC |

| Air | min. 600 kPa |