Online Particle Size Analyzer

01 มิถุนายน 2566

ผู้ชม 212 ผู้ชม

Online Particle Size Analyzer Model: BT-Online Series Particle Size Analyzer

Introduction of BT-Online Series Particle Size Analyzer

The BT-Online series particle size analyzer currently comprises a single model, namely the BT-Online 1 online particle size analyzer. This analyzer is primarily utilized for monitoring particle size in real-time and maintaining quality control in powder manufacturing processes. Although it finds extensive application in the cement industry, it has the potential to benefit numerous other industries by enabling online process control, thereby enhancing production capacity, decreasing energy and waste expenses, and ensuring products are created to a more precise specification through feedback control.

Driven by tandard Operating Procedure (SOP) and integrated with different control platforms and protocols, the BT-Online 1 provides real-time particle size measurement results for dry process lines 24/7. Optional feedback control can be therefore carried out. With the automatic alignment system, uninterruptible power supply (UPS), and abnormal pressure protection, the BT-Online 1 possesses strong environmental adaptability, offering monitoring of the process line with minimal manual intervention.

Features and Benefits

● Automatic sampling method

● Anti-static sampling pipeline

● Multi-stage air filtration system

● Automatic control system

● Reduced energy consumption

● High return on investment

| BT-Online 1 | |

| Particle size distribution | Dry powder |

| Theory | Laser diffraction |

| Mie and Fraunhofer | Analysis theory |

| Typical interval measurement time | ≥1 min |

| Measurement range | 0.1 - 1000µm |

| Number of size classes | 88 customized grades |

| Accuracy | ≤3% (GBRM D50) |

| Repeatability | ≤3% (GBRM D50) |

| Resolution ratio | Single peak, double peak, multi-peak |

| Red light | Max. 3mW, Semiconductor optical fiber laser, 635nm |

| Lens arrangement | Single lens |

| Lens design | F-Theta Lenses |

| Effective focal length | 223mm |

| Arrangement | Log-spaced array |

| Quantity | 68 pieces |

| Light path adjustment | Intelligent automatic alignment |

| Dispersion type | Dry |

| Air flowrate | 400-6000L/min |

| Pressure | 0.5-0.8MPa |

| Air filter | 0.3µm, 0.01µm, water, oil |

| 21 CFR Part 11 | Enable |

| SOP Designer | Enable |

| Report | More than 14 formats report |

| Auto test | Enable |

| Data export | EXCEL, PDF, WORD, JPG and etc. |

| Laser class | Class I laser product |

| Supply voltage | 220VAC |

| Dimension | 800mm x 280mm x 280mm (L x W x H) |

| Weight | 21kg |

| Computer interface | At least one USB2.0 port required |

| Operation system | Windows XP, Windows 7,8 or 10 |

| Hardware specification | Intel Core I5, 4GB RAM, 250GB HD |

Performance

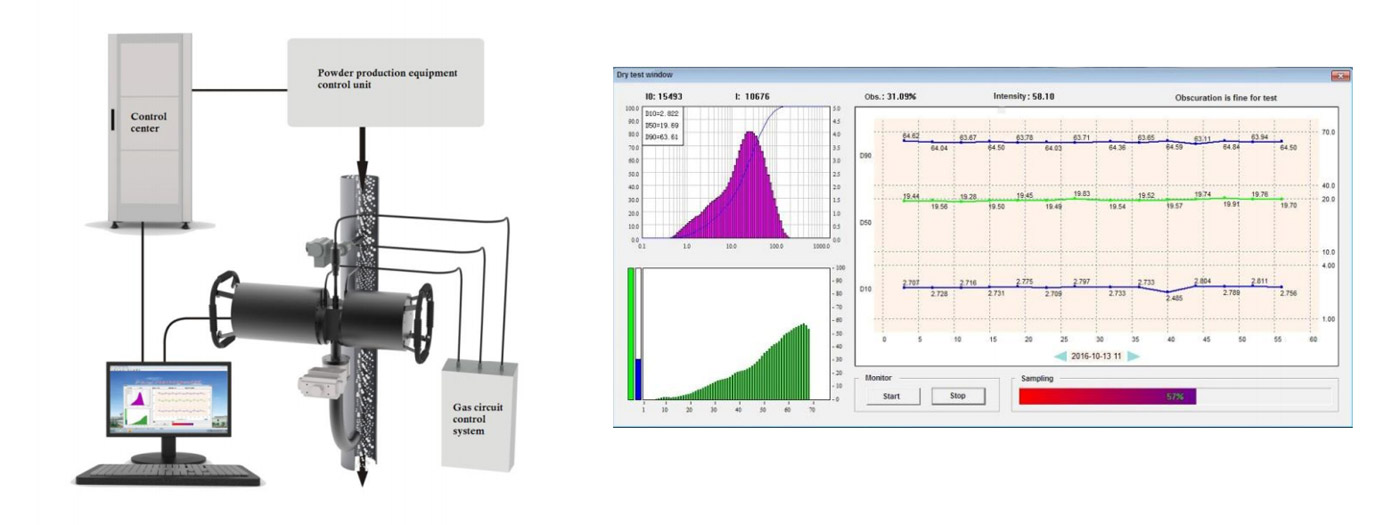

1. Real-time Control System

As well as being able to continuously monitor particle size, the system also has a function for real-time feedback and control. The system will collect real-time size data and perform calculations against the particle size control limits. It automatically generates the feedback signal to the control center. This closed loop feedback control system will achieve better quality improvement, higher efficiency, reduce wastage and save energy.

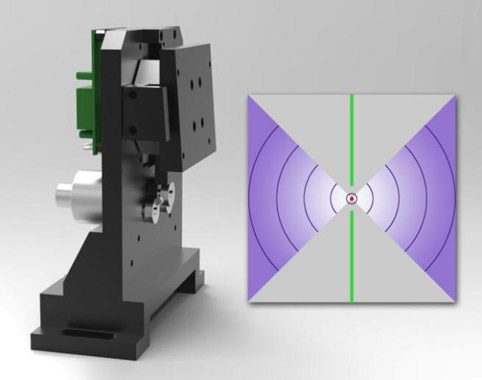

| 2. Automatic Centering Guarantees perfect conditions of the optical system By moving the laser detector center point to the focus point of the lens before each test, the automatic centering function guarantees perfect conditions of the optical system, therefore providing accurate and repeatable testing results. |

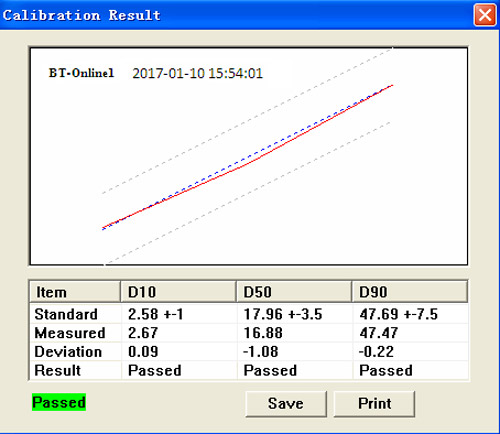

3. Accuracy Calibration Maintain accurate datum lifetime This function maintains operating parameters at consistent conditions, producing consistent and reproducible measurement across the board for all instruments, old and new |

|

|

|

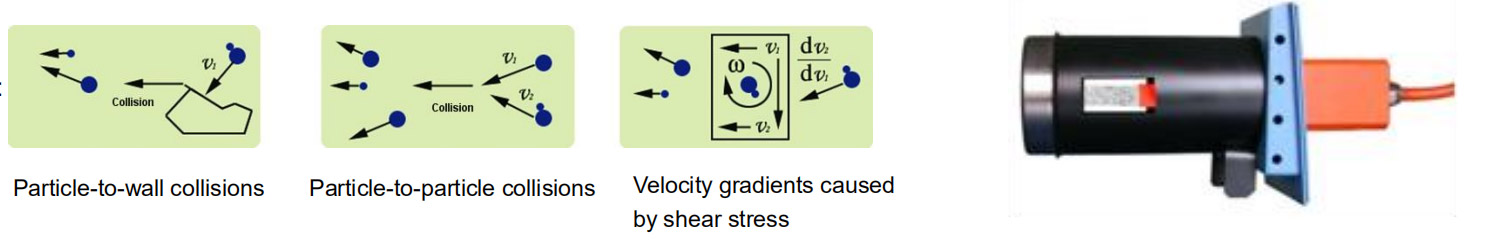

4. Reliable Sampling System

Sample dispersion is achieved by accelerating the powder through a venturi. The "backflush" and tapered pipe design prevents blockage of the sampling tube, and keeps the residual powder clean, ensuring the accuracy and continuity of real-time testing.

Three different dispersion mechanisms can act upon the sample

|

5. Versatile Functionality of the System The system has power interruption protection and over-pressured protection functions. Under these abnormal operating conditions, it will initiate an automatic shutdown

|

| 6. Contamination Prevention Optics System Using the controlled principle of aerodynamics, we devised the double air-cushion lens protection system. The contamination prevention technology will form an invisible double air shield between the sample stream and the lens, eliminating the optics from contamination from sampling, as well as a dust-prone environment. With this technology, the ultimate goal of a long duration of sustainable operation, providing real-time, continuous particle size monitoring and control can be realized. Accuracy and continuous monitoring of the production data can be achieved. |