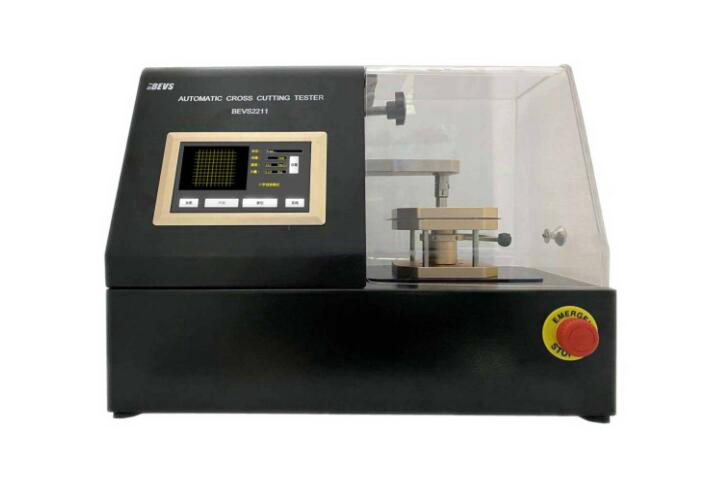

Automatic Cross Cutting Tester

Introduction:

BEVS 2211 Automatic Cross Cutting Tester is a new high-efficiency coating adhesion performance test equipment. The adhesion level of the coating on the substrate can be easily and quickly determined. It is time-saving, labor-saving and of good repeatability. The equipment complies with a variety of standards, the grid angle is accurately adjustable, and it is compatible with the preparation of the scratches required before the salt spray corrosion test. It is simple and quick to operate, which can effectively avoid problems such as insufficient or uneven manual cross-cutting.

Features:

Color capacitive touch screen

High precision, good repeatability

The platform automatically rotates and moves

Compatible with single-blade, multi-blade cross cutting head to cut panels for adhesion and salt spray corrosion tests

Digital display load pressure which is adjustable to meet the needs of different coating thicknesses

Speed and stroke length are adjustable to meet the test panel of different sizes

Compatible with a wide range of sample thickness

Manual clamping of samples, reliable and stable

Adjustable cutting space

Adjustable cutting lines

Cutting angle adjustable

Cross-cut program can be set and saved

Technical info:

Test panel size: L(110-170) x W(50-110) x H(0.2-20)mm

Load pressure: 1-40N

Cross-cut angle: 0-90°

Cross-cut spacing: 1-4mm

Number of grids: 1-11

Cross-cutting speed: 5-80mm/s

Cross-cut stroke length: 40-65mm

Power supply: 110V or 220V, 50/60Hz

Power: 300W

Machine size: L580 x W310 x H440mm

Standard:

ISO 2409-2013, ASTM-D3359-2017, GB/T 9286-1998, ISO 17872-2007

Order info:

BEVS 2211 Automatic Cross Cutting Tester