The new Laser Misting Measuring Unit

24 พฤษภาคม 2566

ผู้ชม 140 ผู้ชม

The new Laser Misting Measuring Unit

The Novomatics Laser Misting Measuring Unit allows automated misting evaluation of printing inks at a high degree of accuracy and reproducibility. It operates in combination with AlphaTack Plus or LithoTack II and is so part of Novomatics modular printing ink measuring system.

Due its automatic controlled test conditions the laser-based methodology offers significant advantages over the usual misting testing methods, like visual observation of white papers or vacuum cleaning filters. It is an objective, quantitative method and so independent of the operator.

Features:

• quantifies flying ink droplets in real-time

• integration into standard tack tests of AlphaTack Plus or LithoTack II

• misting results are printed in same report like tack results

• operator independent, fully automated measuring system

• stable measurements over the lifetime of the instrument

• accurate, reliable and easy to operate

• cost savings because of no extra operator time and accurate measurements

• usually no cleaning needed, but if so, done within a few seconds

• space saving, compact design

• easy installation by “plug and play”

• ideal for QC and R&D

• ideal for use outside of the laboratory

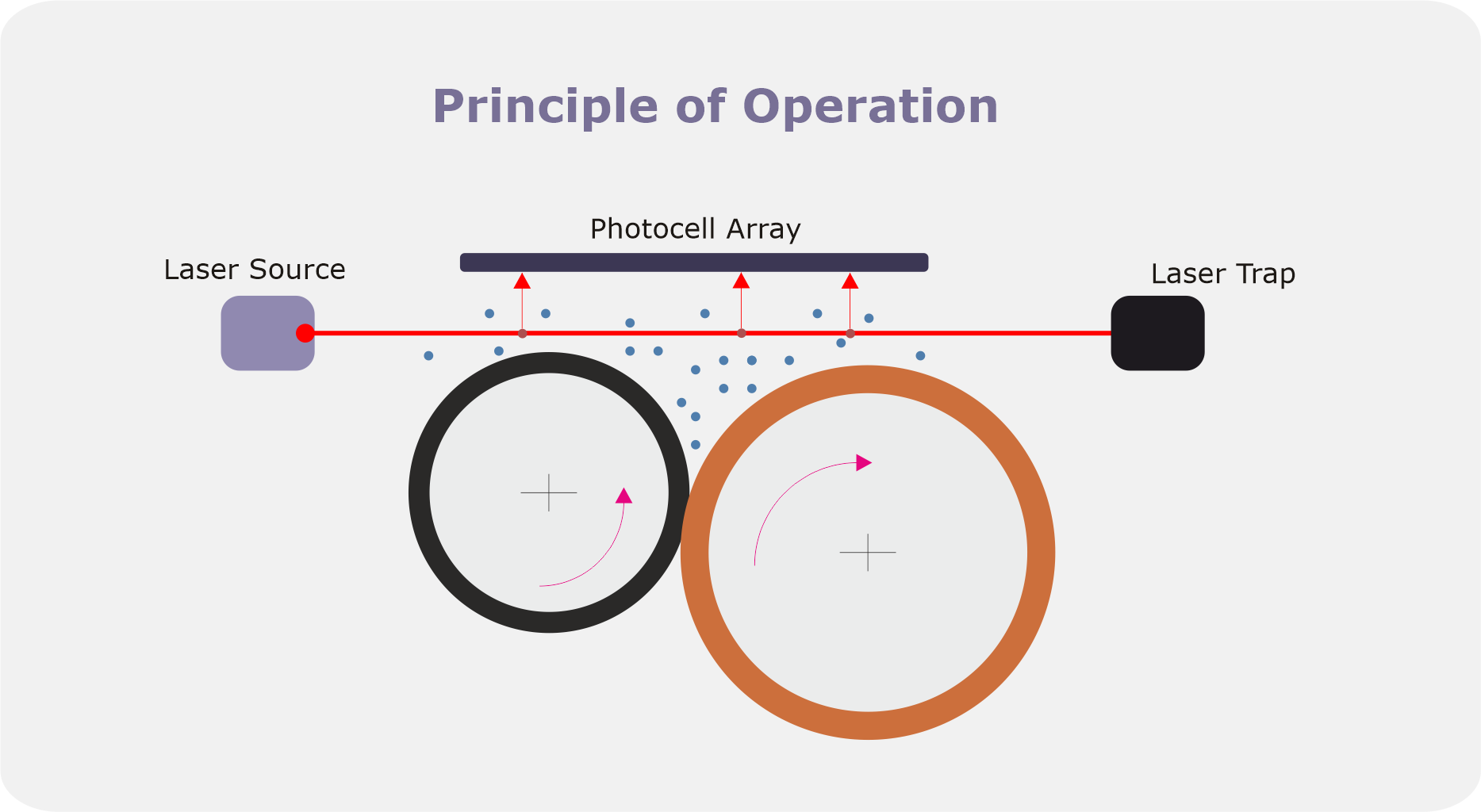

Operation principle of Laser Misting Measuring Unit

The new Novomatics Laser Misting Measuring Unit overcomes the principal problems of the current subjective methods.

A laser beam is placed close to roller nip. Ink droplets which are passing that beam reflect its light. A photocell array nearby receives that reflected light.

The Laser Misting Measuring Unit is able to quantify the droplets concerning their number and size. All necessary calculations are performed in real-time resulting in a misting representing parameter. This parameter is recorded and reported like other ink related parameter.

The laser beam is modulated by a unique signature. That’s why only the light that contains that signature is considered by the light receiver. The light of other sources in ambient is actively cancelled.

For operators’ safety the laser power is very low. Further it is stopped into a laser trap and so it is impossible to be exposed to.