Automatic Panel Spray Station

Introduction:

The BEVS 3231 automatic panel spray station utilizes a portable paint syringe that allows for small dosages of paint, quick sample changes, and no cleaning. The sealed, controlled "booth" design allows the station to be used in a wide range of applications in production plants, laboratories and other locations.

The station is operated by man-machine interaction. The operator puts the substrate board on the X-axis rotating platform, puts the syringe containing the coating material to the specified position on the Z-axis, closes the operating door, and then activates the equipment to complete the spraying according to the preset program automatically.

Standard : GB/T 1727, ASTM D823-2018

Product Features:

■ Nozzle no-cleaning

■ 10-inch high-definition touch screen design

■ Intelligent programming of the spraying process

■ Fully automatic spraying with two axes

■ Simultaneous spraying in both directions

■ Adjustable height of the spray head from the substrate plate

■ Adjustable spraying width and atomization parameters according to needs

■ The equipment can be disassembled into two tiers for easy transportation and access to height-restricted spaces such as laboratories.

Product Functions

(1) Two axes (X, Y) automatic control, Z-axis spraying distance can be adjusted, X, Y-axis according to the established program automatic control operation, Z-axis according to the actual need to manually adjust the gun distance.

(2) Customized programming can be carried out according to the specific situation, inputting parameters such as spraying movement speed, spraying atomization pressure, number of times of spraying, start spraying position and end position, etc., to achieve precise coating effect.

(3) Hundreds of spraying programs can be preset and stored, one-key call, convenient and quick.

(4) The interface real-time display of experimental parameters, including the current number of times sprayed, the remaining number of times sprayed.

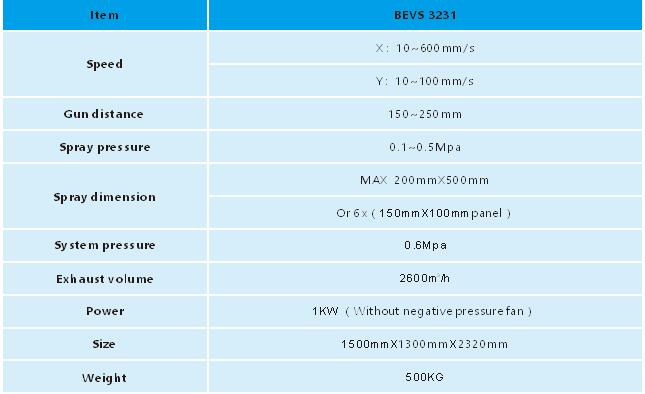

Main Parameters