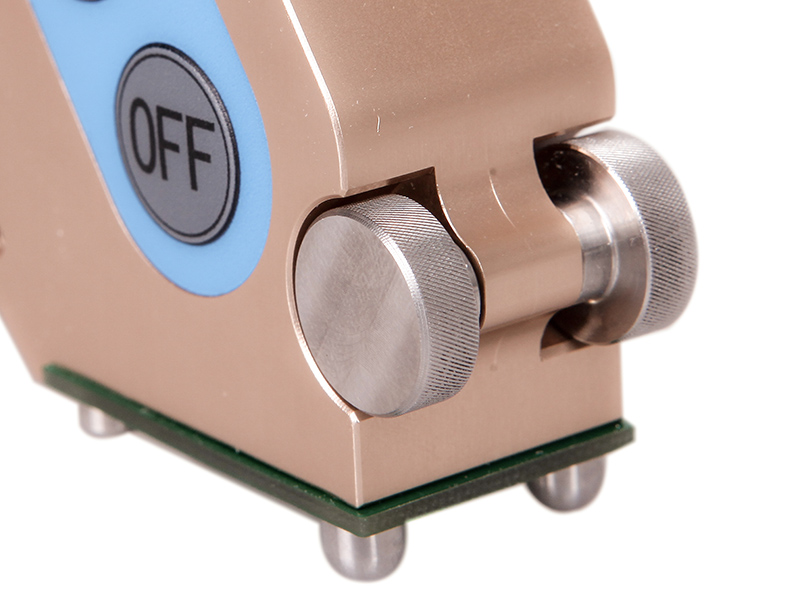

Paint Inspection Gauge

Introduction:

BEVS1707 PIG is using destructive method to measure coating thickness, containing single and multiple coats, applied on all of substrates, e.g.:aluminum, iron, plastic, wood, concrete, glass etc.

Using Principle:

A cut is made on the test surface with a V-shaped tool.The coating thickness can be measured with the built-in microscope underthe LED light.

Standard:

ASTM D4138, DIN 50986, ISO 2808

Technical Specification:

| Cutter | Cut Angle | Range(μm) | D Factor(μm) |

| No.1 | 45° | 20-1800 | 20 |

| No.2 | 63.4° | 10-900 | 10 |

| No.3 | 84.3° | 2-180 | 2 |

Measurement Principle:

Operating Steps:

| Step | Illustration | Description |

| 1 |  |

Prepare the inspecting area |

| 2 |  |

Draw a line with the marker pen on the surface |

| 3 |  |

Cut the coating vertically and make sure it is lacerated |

| 4 |  |

Read the graduation-scale with the microscope to attain thickness |

Order Information:

BEVS 1707 Paint Inspection Gauge, including 3 x cutters (No. 1, 2 and 3 each), 1 x battery, 1 x marker pen and 1 x carrying case

Accessories:

BEVS 1707/P/010 Cutter No.1

BEVS 1707/P/020 Cutter No.2

BEVS 1707/P/030 Cutter No.3