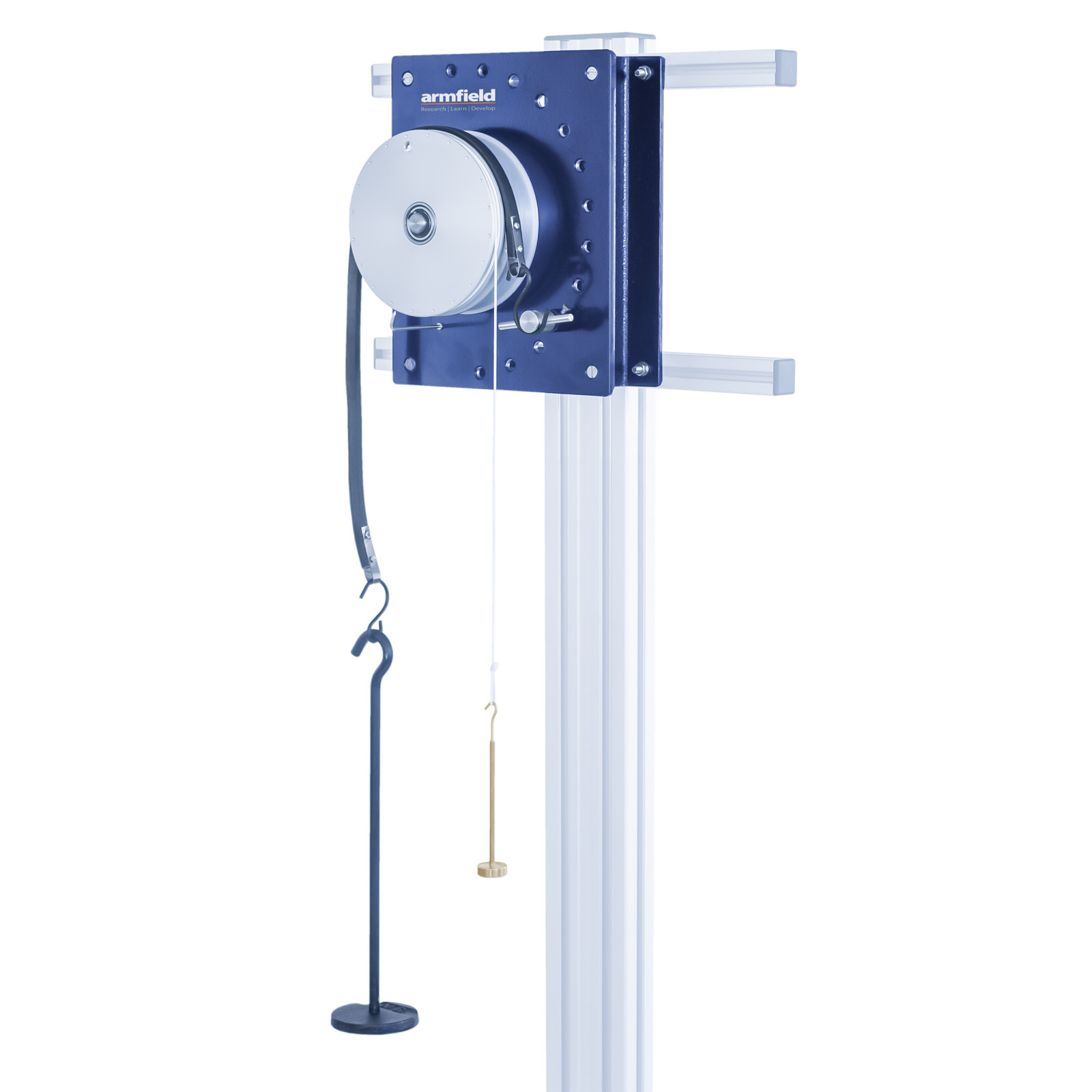

Friction of Belts Apparatus

20 เมษายน 2566

ผู้ชม 442 ผู้ชม

DESCRIPTION

The apparatus consists of a wall mounted pulley with a loaded belt. The pulley is made of aluminium and has two machined grooves to suit a flat, vee belt and a rope. Each belt fits into its respective groove during testing.

For a given belt tension and angle of lap, a turning moment can be applied by adding weights to the pulley drive hanger. The idea is to determine the torque which just causes the pulley to turn, and so to find the ratio of the belt tensions. This enables the belt tension equation to be verified and the coefficient of friction to be determined.

The angle of lap can be easily varied by placing one end of each belt at different angular positions on the wall bracket. A removable pin and bar are used to enable the various angular positions to be achieved.

EXPERIMENTAL CONTENT

- To observe the relationship between the tensions in the two sides of a belt

- To assess the differences between vee, rope and flat belts

- To determine the coefficient of friction between the pulley and belt for the belt sections

- To investigate the effect of angle of lap

TECHNICAL SPECIFICATIONS

- Single large pulley

- Flat groove and 40° ‘V’ groove

- 150mm effective groove diameter

- Pulley timing grooves at 18° intervals

- Belt anchor points at 15° intervals

- Safety interlock to stop pulley rotating

FEATURES & BENEFITS

- Can be mounted to the SV100 Bench Mounted Frame

- One pulley caters for three belts. No interchanging of pulleys

- Constant tangential drive of pulley

- Three belts supplied; flat, vee and rope

- Customer specific belts can be used

- Full set of weights and hanger supplied