Multi-function Process Control Teaching System

19 เมษายน 2566

ผู้ชม 188 ผู้ชม

DESCRIPTION

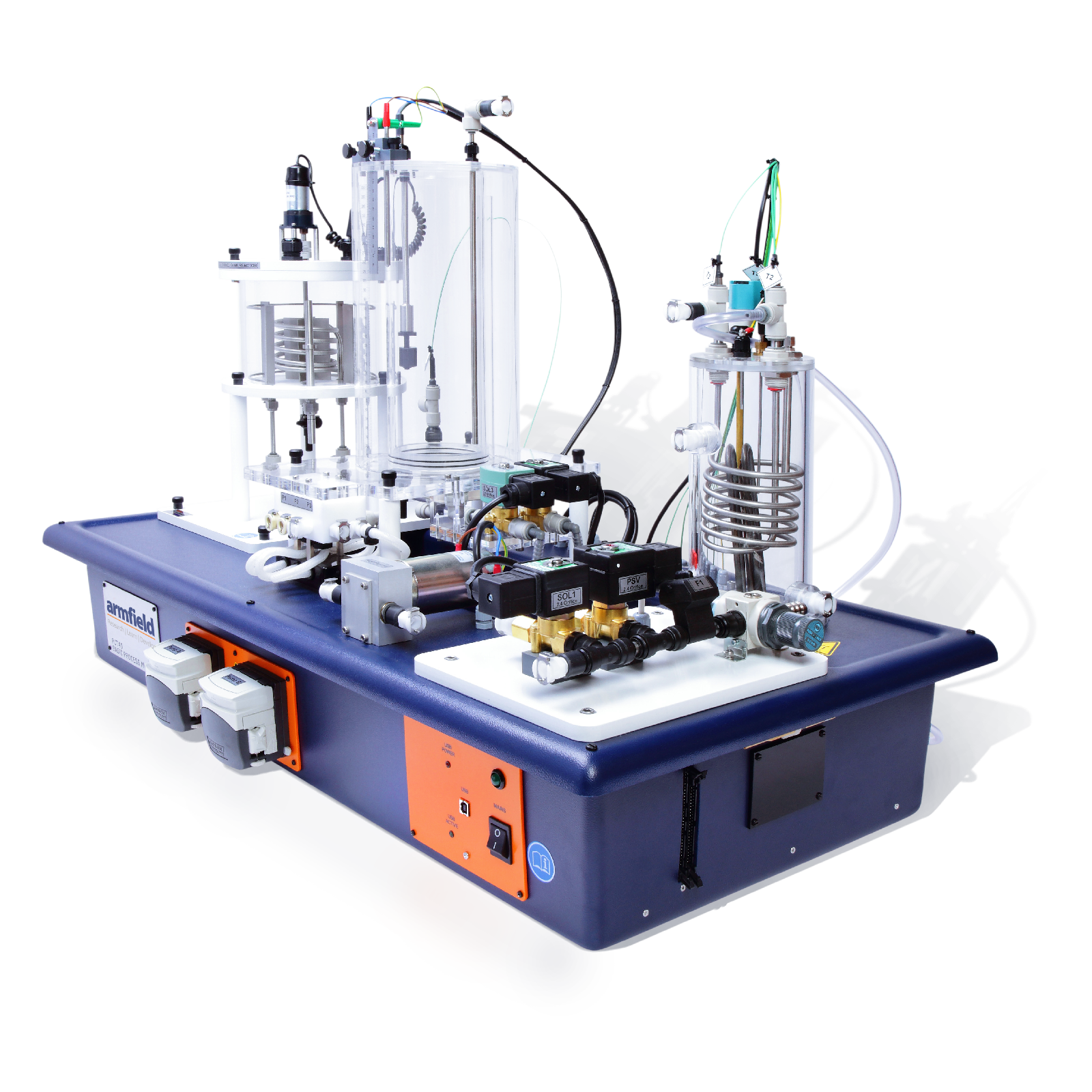

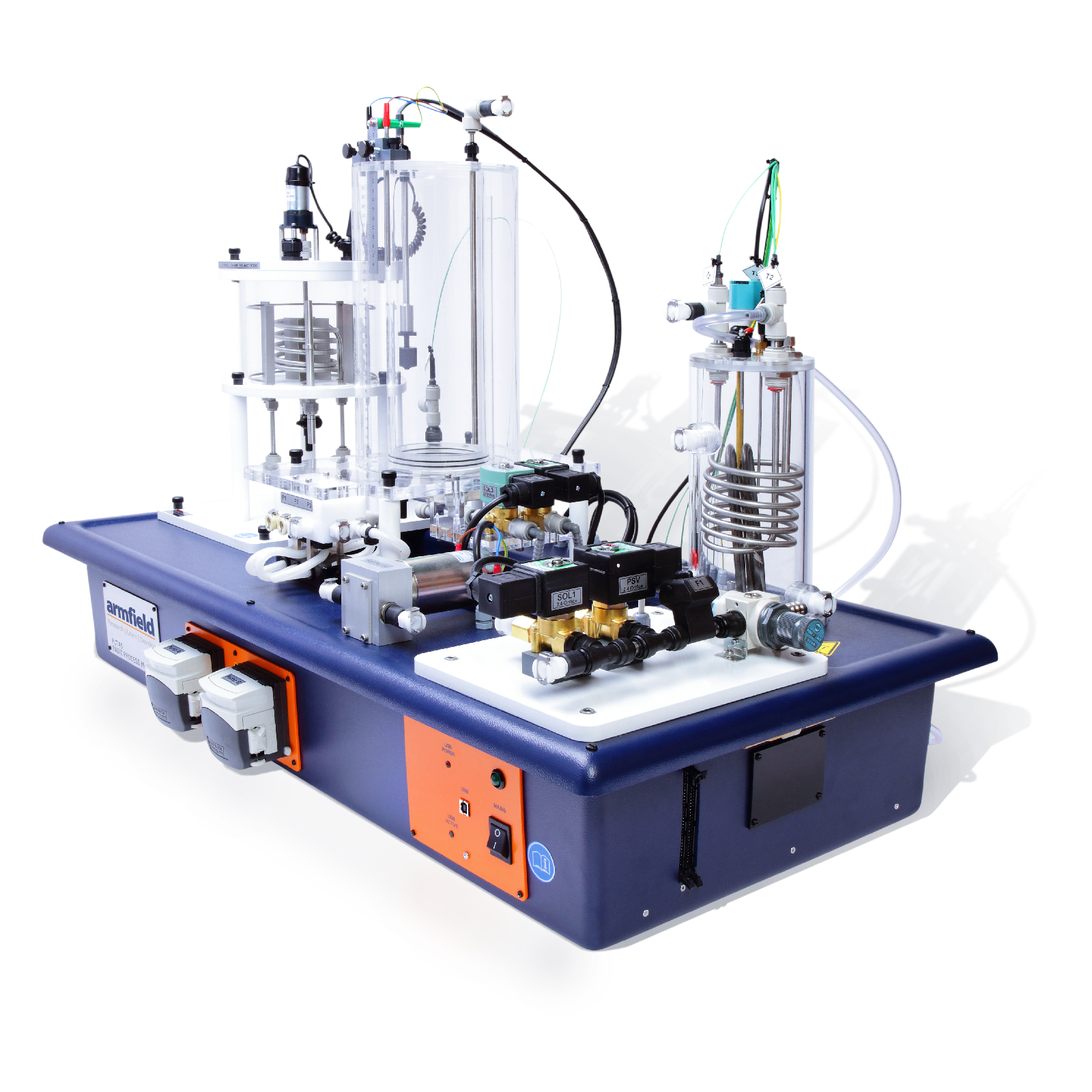

PCT40 BASIC PROCESS CONTROL SYSTEM

The PCT40 contains everything that is needed to perform a range of single-loop process control experiments in conjunction with a PC.

It includes a variable volume process tank, a hot water tank with electric heater and indirect heating/cooling coil, a hot water pump, two non-dedicated pumps, three on/off solenoid valves and a proportioning valve. The instrumentation includes temperature sensors, two differential water pressure sensors, a mechanical level sensor (float switch) and an electronic level sensor (conductivity). The inlets and outlets of the various pumps, valves and tanks incorporate self-sealing quick release fittings. This enables the configuration to be quickly changed, offering a wide variety of different loops.

The PCT40 includes a computer interface (USB), and all of the parameters can be controlled directly from the computer, (i.e. the pump speeds, the valve positions and the heater power). The computer also displays the readings from the various measurement sensors.

The software supplied with the unit includes on/off, time proportioned and proportional/integral/derivative (PID) algorithms where all the parameters are easily accessed and adjusted by the user. This approach means that a separate electronic console is unnecessary for most applications.

The flexible nature of the system also enables a wide variety of different disturbances to be applied to the loops to permit the effectiveness of the control parameters to be compared. As all these disturbances are under software control, they can be repeated precisely during the optimisation process, thus enabling an excellent degree of fine-tuning to be implemented.

A pressure regulating valve with filter is also included to isolate the equipment from fluctuations in the water supply pressure.

The type of loops achievable with the basic PCT40 include:

- Tank water level by varying input flow

- Water flow rate by varying pump speed

- Temperature of water in a vessel by varying the heater power

- Temperature of water heated indirectly by varying the flow rate

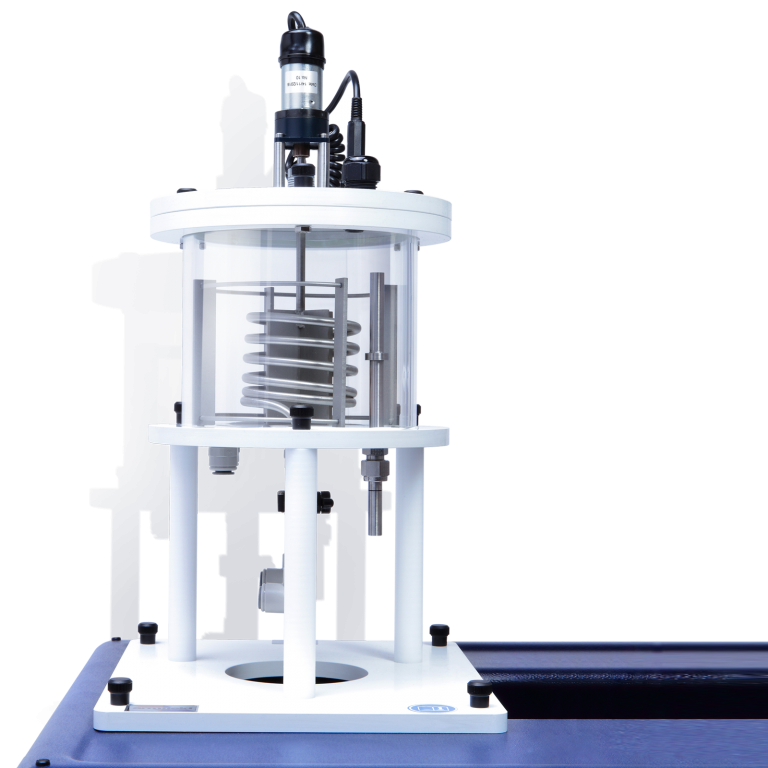

PCT41 PROCESS VESSEL ACCESSORY

The PCT41 extends the capability of the basic PCT40 by adding an additional process vessel, complete with a heating/cooling coil and a stirrer. The inputs and outputs incorporate quick release fittings, enabling the PCT41 to be added quickly and easily.

The PCT41 also includes a conductivity probe to enable cost-effective fluid property demonstrations to be performed.

The addition of the process vessel enables more complex process control problems to be addressed, including remote set point demonstrations. Again these all take place with the repeatability advantages that electronic and software control brings.

Additional loops that can be implemented with the PCT41 include:

- Single loops in combination:

- Conductivity control of reactor contents by varying flow rate of one component

- Temperature control of reactor contents by varying heating fluid flow rate

- Temperature control of heating fluid by varying heater power

Remote set point control:

- Ratio control of two flows (Fig 1)

- Cascade control of conductivity and flow (Fig 2)

- Feed-forward control of flow to flow

- Feed-forward control of flow combined with feedback control of conductivity

PCT42 PH SENSOR ACCESSORY

The PCT41 includes a conductivity probe as part of the basic supply. This conductivity probe can be used to demonstrate fluid property control systems without the maintenance problems, which can be experienced with pH probes. However, as pH control is probably the most common industrial application of this type of control system, users may wish to implement true pH control loops. This can easily be implemented by adding the PCT42 pH Sensor Accessory to the combined PCT40 + PCT41 systems.

PCT43 ELECTRONIC CONSOLE

The PCT43 is an electronic console that can be used to control the PCT40 (+PCT41/42) instead of a computer. It includes controls for the pumps, valves and heater, plus a display for the sensors. It incorporates a commercial PID controller, complete with RS232 interface. Other facilities include four 20mA interfaces and selector switches to enable many of the different configurations to be implemented without using external jumper connections.

The PCT43 enables all of the PCT40 and PCT41 single-loop configurations to be implemented without using a computer. Using this console also enables the sensor data to be logged and displayed on a computer (using the PCT40 USB interface), but with the control functions being implemented in the PCT43 hardware, rather than the computer software.

Facilities include:

- Use of a commercial PID controller

- Simple interfacing to other PLC and/or PID controllers

- Use of four 20mA interfaces

- Use of serial communications (RS232) in a control system

- Simple SCADA demonstration (requires PC)

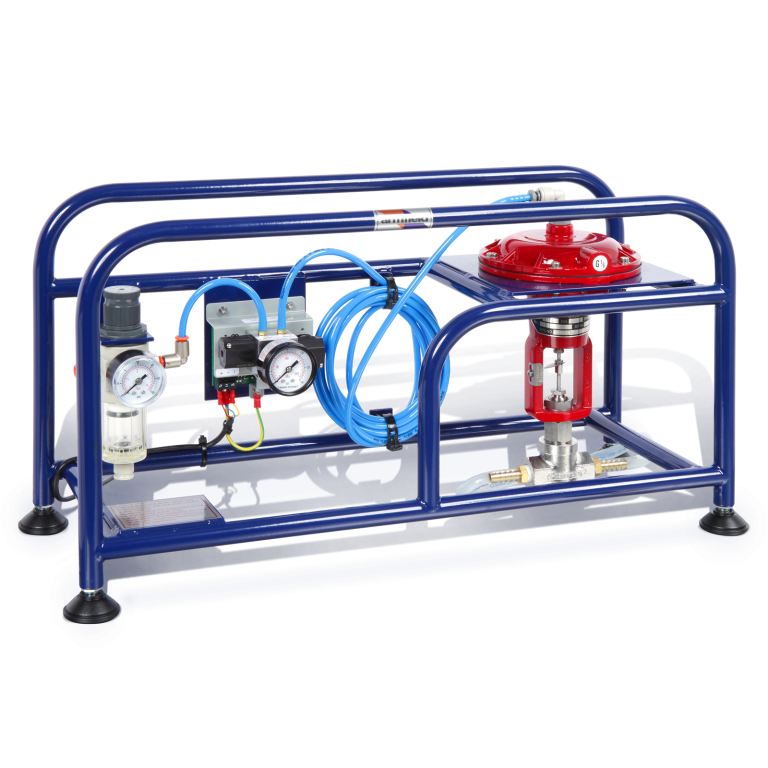

PCT44 PNEUMATIC VALVE MODULE ACCESSORY

The PCT44 is a pneumatic control valve, plus associated components, for use with the PCT40/41 system. Retaining the flexible concept of the whole range, it can be plumbed into many of the flow control loops, and provides a good illustration of pneumatic valve technology.

Note: This accessory requires a compressed air supply

CAPABILITIES

- The basic PCT40 is used under computer control to demonstrate a variety of single control loops. It can be quickly reconfigured between processes, such as level control, temperature control, flow control and pressure control. The advanced software enables the student to change the control parameters, record results and analyse the results for the different configurations

- The PCT41 expands on the capabilities of the PCT40, and offers a wider range of control loops and strategies, including remote set points, dual loops, and fluid property control (using conductivity). Again all of these are under software control

- Other accessories are available, including a control console with commercial PID controller, plus a pH probe and a pneumatic valve for those wishing to implement specialised demonstrations

- Large range of demonstrations – configurable by the end user

- Computer control as standard

- Computer generated loop disturbances for repeatability, enabling small variations in control parameters to be investigated

- Flexible system, suitable for project work