Flowmeter Demonstrator

26 พฤษภาคม 2566

ผู้ชม 517 ผู้ชม

DESCRIPTION

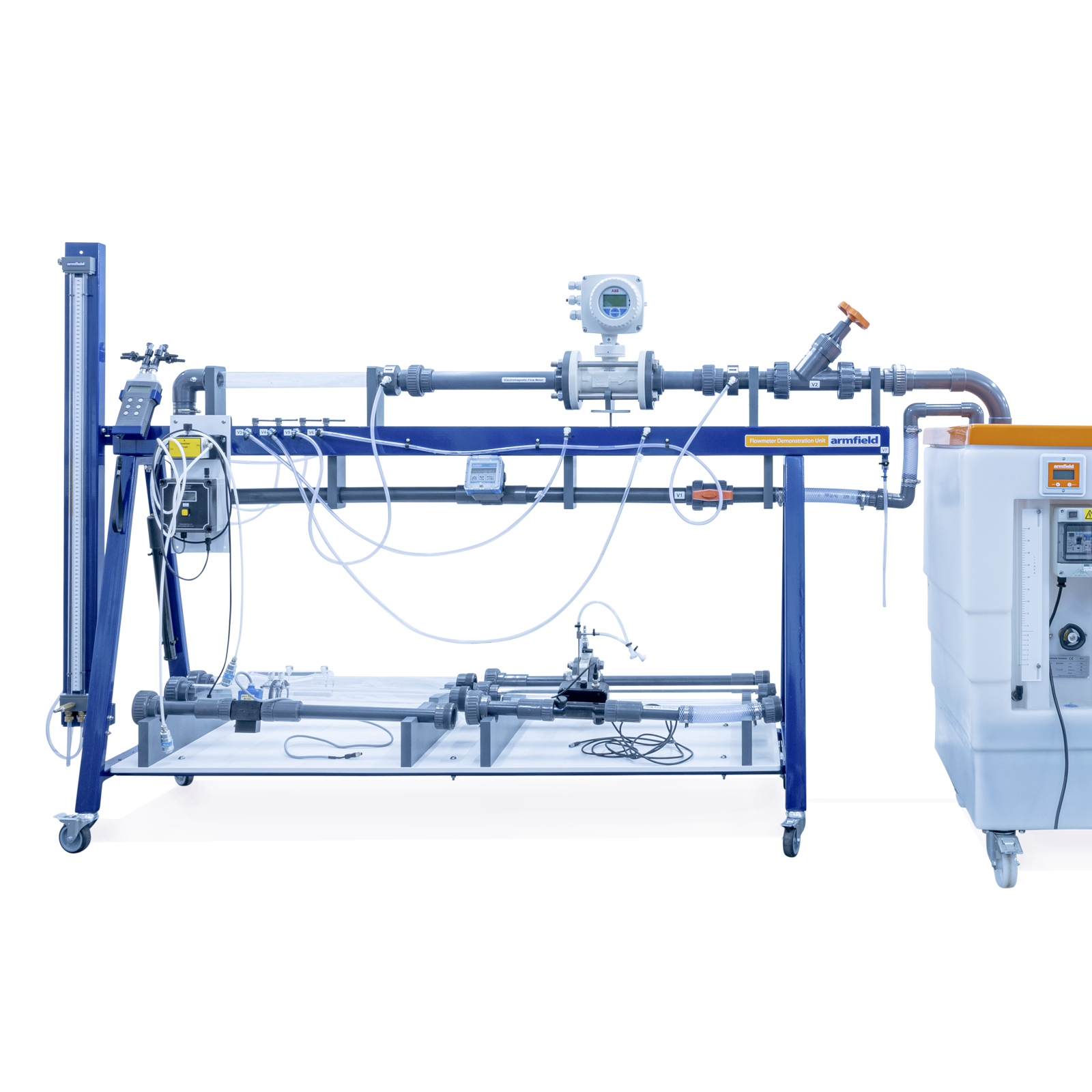

The C9-MKII Flowmeter Demonstrator is designed to allow the user to understand the different types of flowmeters commonly found in use throughout various industries.

The flowmeters available are of both electronic and non-electronic types with the options covering both mechanical and passive systems.

The experimental content includes the measurement of pressure loss across a range of flowmeters and the direct use of flowmeters for the determination of flowrates, either visually or by the use of pressure differential. The unit is supplied with armBUS software as standard. Including manual data entry for non electronic flow meters and automatic datalogging for electronic flow meters. (Requires AIU-4)

The unit can be used to:

- Understand the practical use and characteristics of Industrial flowmeters

- Assess the pressure drop which occurs with flowmeters within a simple piped system

- Understand flow measurement by using flowmeters which relay on a pressure change across the system

- The unit comprises of a framework that incorporates pipework with valves, a reference flowmeter, water and digital manometers and a test section for the insertion of flowmeters undergoing testing. The unit is designed to utilise the Armfield F1-10 Hydraulics Bench which provides a pumped reservoir of water to recirculate through the C9-MKII unit making efficient use of water. The flow rate of the system can be varied by use of a simple control valve to study the effects of changing flow in relation to pressure loss in a flowmeter

- The optional AIU4 Interface Console links the flowmeters with electronic outputs to the laptop or PC. The console interprets the signals received into the correct output format for the armBUS™ software. The console has a 24vDC power supply to reduce the risk of high voltage incidents with contact with water

EXPERIMENTAL CONTENT

- Comparing the use, application and limitations of various types of flow meter

- Considering the implications of flow meter selection on performance, accuracy, convenience, cost and head loss

- To demonstrate the use of one or more alternative flowmeters for the measurement of flow rate in a closed conduit, and to determine the flowmeter characteristics, primarily the pressure drop across the meter as well as it’s functionality

- Understanding the principles on which different types of flow meter are based

- Using manometers to measure pressure drop

- I nvestigating the effect of air in the hydraulic stream on flow meter performance

- Understanding the application of Bernoulli’s Theorem

- To demonstrate the application of an Orifice Plate, Venturi and Pitot tube in the measurement of flow rate in a closed conduit

- To demonstrate the use of one or more flowmeters for the measurement of flow rate in a closed conduit, and to determine the flowmeter characteristics. Including Electromagnetic, Ultrasonic, Paddle Wheel, Turbine Wheel, Variable Area with a Transducer, Vortex Flowmeter, Orifice Plate Flowmeter with Transducer, Bypass and Baffle Plate

TECHNICAL SPECIFICATIONS

- Digital Differential Manometer Operating range – 0 – 2000 mBar (0 – 1500mmHg)

- Water Manometer – Operating range – H12-2 1000 mm H2O

- Electromagnetic Flowmeter – 50 – 200 ltr/min.

- Ultrasonic Flowmeter – 5 – 240 ltr/min.

- Venturi Nozzle

- Pitot Tube

- Orifice Plate Flowmeter

- Paddle Wheel Flowmeter – 15 – 150 ltr/min.

- Turbine Wheel Flowmeter – 15 – 150 ltr/min.

- Variable Area Flowmeter – 10 – 100 ltr/min.

- Variable Area Flowmeter with Transducer – 15 – 150 ltr/min.

- Vortex Flowmeter – 8.3 – 133 ltr/min.

- Orifice Plate Flowmeter with Transducer – 30 – 150 ltr/min.

- Bypass Flow Meter – 20 – 100 ltr/min.

- Baffle Plate Flow Meter – 15 – 150 ltr/min.

- AIU4 unit – Supplied with Hall counter input, 4-20mA signal input, 0-5v signal input, USB Out

FEATURES & BENEFITS

Modular Flow meter demonstration unit optionally supplied with 13 flowmeters

- Utilises Armfield F1-10 Hydraulics bench

- Allows students to understand the advantages and disadvantages of various flowmeters

- Asses the pressure drop which occurs with flowmeters within a simple piped system

- Understand the practical use and characteristics of Industrial flowmeters

- Supplied with Armbus software as standard

- Understand flow measurement by using flowmeters which relay on a pressure change across the system