เครื่องกวนผสมสารอนุภาคนาโน (Ultrasonic Liquid Processor)

28 กันยายน 2565

ผู้ชม 1474 ผู้ชม

Industrial Sonomechanics - ผู้ผลิตเครื่องผสมสารให้เป็นเนื้อเดียวกันด้วยหลักการ Ultrasonic เครื่องกวนผสมสารอนุภาคนาโน เครื่องผสม Nanoemulsion เครื่องสกัด cbd ด้วยคลื่นอุลตร้าโซนิค เครื่องสกัด cannabinoid เครื่องผสมสารอนุภาคนาโน (nanostabilizer) ให้เข้ากับน้ำมัน สมุนไพร เครื่องดื่ม เครื่องผลิต nanoemulsion ที่ละลายน้ำได้ เครื่องไล่ก๊าซออกจากน้ำมัน(Degassing) เป็นต้น มีให้เลือกสามแบบ ได้แก่ รุ่นที่ใช้ในห้องแล็ป (lab scale) เครื่องขนาดโรงงานต้นแบบ (Pilot scale) และระดับอุตสาหกรรม (Industrial scale) สามารถนำไปใช้งานในหลากหลายอุตสาหกรรม เช่น

- Medical Cannabis - สารสกัดจากกัญชง กัญชาเพื่อการแพทย์

- Pharmaceutical & Nutraceutical - ยาและอาหารเสริม

- Cosmetic & Dermatological – เครื่องสำอางและผลิตภัณฑ์บำรุงผิว

- Food & Beverage - อาหารและเครื่องดื่ม

- Pesticide & Insecticide - ยาฆ่าแมลง

- Candle Wax, Oil & Adhesive - แว็กซ์ น้ำมัน และกาว

- Paint, Ink & Coating - สี หมึกพิมพ์ และสารเคลือบผิว

LSP-600 Ultrasonic Liquid Processor

The LSP-600 ultrasonic liquid processor is designed for feasibility testing and procedure optimization. It is capable of continuous operation for up to 1 hour at a time and can handle liquid volumes up to 2 L.

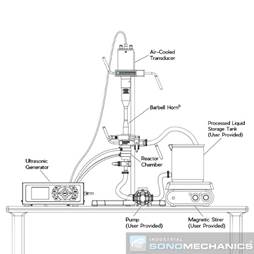

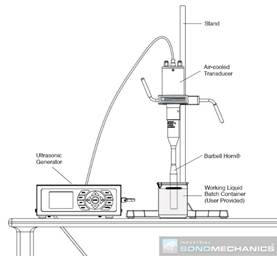

LSP-600 - Laboratory-Scale Processor / LSP-600 Batch Configuration Schematic

SPECIFICATIONS DOWNLOADS VIDEOS

The LSP-600 ultrasonic liquid processor comes standard with : 600 W ultrasonic generator, air-cooled transducer, full-wave Barbell Horn®, medium-duty support stand, spanner wrench set, and noise reduction ear muffs. Optional items include : flow-through reactor chamber (flow cell), magnetic stirrer with hotplate, water chiller, air blower, 2 L process vessel, peristaltic pump, beaker, NanoStabilizers®, and filters.

The LSP-600 processor can be used in batch and flow-through configurations (see schematics on the left). Details are available under the SPECIFICATIONS tab.

The LSP-600 processor utilizes patented Barbell Horn® Ultrasonic Technology (BHUT), which makes it possible to generate extremely high ultrasonic amplitudes at any scale of operation. By upgrading to our larger BHUT-based units, the BSP-1200 or ISP-3600, any process optimized with the LSP-600 can be directly scaled-up to a pilot or industrial production environment.

|

LSP-600 Flow-Through Configuration (side view) |

LSP-600 Batch Configuration (front view) |

|

LSP-600 Flow-Through Configuration Schematic |

LSP-600 Batch Configuration Schematic |

BSP-1200 Bench-Scale Processor

The BSP-1200 ultrasonic liquid processor is designed for procedure optimization and medium-scale production. It is capable of continuous 24/7 operation and can handle unlimited liquid volumes.

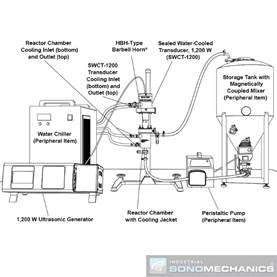

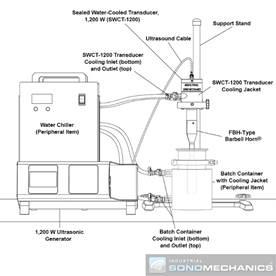

BSP-1200 Flow-Through Configuration including Storage Tank with Integrated Mixer

SPECIFICATIONS DOWNLOADS VIDEOS

The BSP-1200 ultrasonic liquid processor comes standard with: 1200 W ultrasonic generator, water-cooled transducer, half-wave Barbell Horn®, flow-through reactor chamber (flow cell), heavy-duty support stand, spanner wrench set, and noise reduction ear muffs. Optional items include: full-wave Barbell Horn®, storage/mixing tank with integrated mixer, peristaltic pump, water chiller, magnetic stirrer with hotplate, jacketed beaker, NanoStabilizers®, and filters.

The BSP-1200 processor can be used in batch and flow-through configurations (see schematics on the left). Details are available under the SPECIFICATIONS tab.

The BSP-1200 processor utilizes patented Barbell Horn® Ultrasonic Technology (BHUT), which makes it possible to generate extremely high ultrasonic amplitudes at any scale of operation. By upgrading to our larger BHUT-based unit, the ISP-3000, any process optimized with the BSP-1200 can be directly scaled-up to an industrial production environment, while maintaining the same processing conditions and reproducible results.

BSP-1200 Flow-Through Configuration including Storage Tank with integrated mixer (side view)

|

BSP-1200 Batch Configuration |

BSP-1200 Batch Configuration with Stainless Steel Beaker |

|

BSP-1200 Flow-Through Configuration Parts Identification Schematic |

BSP-1200 Batch Configuration Schematic |

ISP-3600 Industrial-Scale Processor

The ISP-3600 ultrasonic liquid processor is designed for industrial-scale production. It is suitable for working with liquid volumes above 1 L, with no upper limit.

ISP-3600 Ultrasonic Processor, Flow-Through Configuration

SPECIFICATIONS DOWNLOADS VIDEOS

The ISP-3600 ultrasonic liquid processor comes standard with: 3600 W ultrasonic generator, water-cooled transducer, half-wave booster half-wave Barbell Horn®, flow-through reactor chamber (flow cell), heat exchanger, heavy-duty support stand, spanner wrench set, and noise reduction ear muffs. Optional items include: storage/mixing tank with integrated mixer, magnetic stirrer with hotplate, peristaltic pump, water chiller, jacketed beaker, NanoStabilizers®, and filters.

The ISP-3600 processor can be used in batch and flow-through configurations (see schematics on the left). Details are available under the SPECIFICATIONS tab.

The ISP-3600 processor utilizes patented Barbell Horn® Ultrasonic Technology (BHUT), which makes it possible to generate extremely high ultrasonic amplitudes at any scale of operation. With the ISP-3600, any process optimized with our smaller units, the LSP-600 or BSP-1200, can be directly scaled-up to an industrial production environment, while maintaining the same processing conditions and reproducible results. Further scale-up is possible by placing several ISP-3600 processors in parallel and/or in series (see schematics on the left).

ISP-3600 Flow-Through Configuration (side view)

|

ISP-3600 Batch Configuration |

ISP-3600 Batch Configuration (side view) |

|

ISP-3600 in use at an industrial plant |

ISP-3600 in use at an industrial plant (close-up) |