เครื่องวัดจุดวาบไฟ (The safe side of flash point testing)

10 สิงหาคม 2565

ผู้ชม 1100 ผู้ชม

Summary

The safe side of flash point testing. The flash point tester ERAFLASH measures in full compliance with the Continuously Closed Cup flash point testing methods ASTM D6450, ASTM D7094 as well as the European equivalent IP620. ASTM D7094 shows no statistical bias to the former ASTM D93 Pensky Martens method. The sample volume is only 2 ml. During measurements an electric arc ignites the sample vapor and the analyzer determines the flash point by the pressure change inside the closed cup. Flash point testing never was safer and easier.

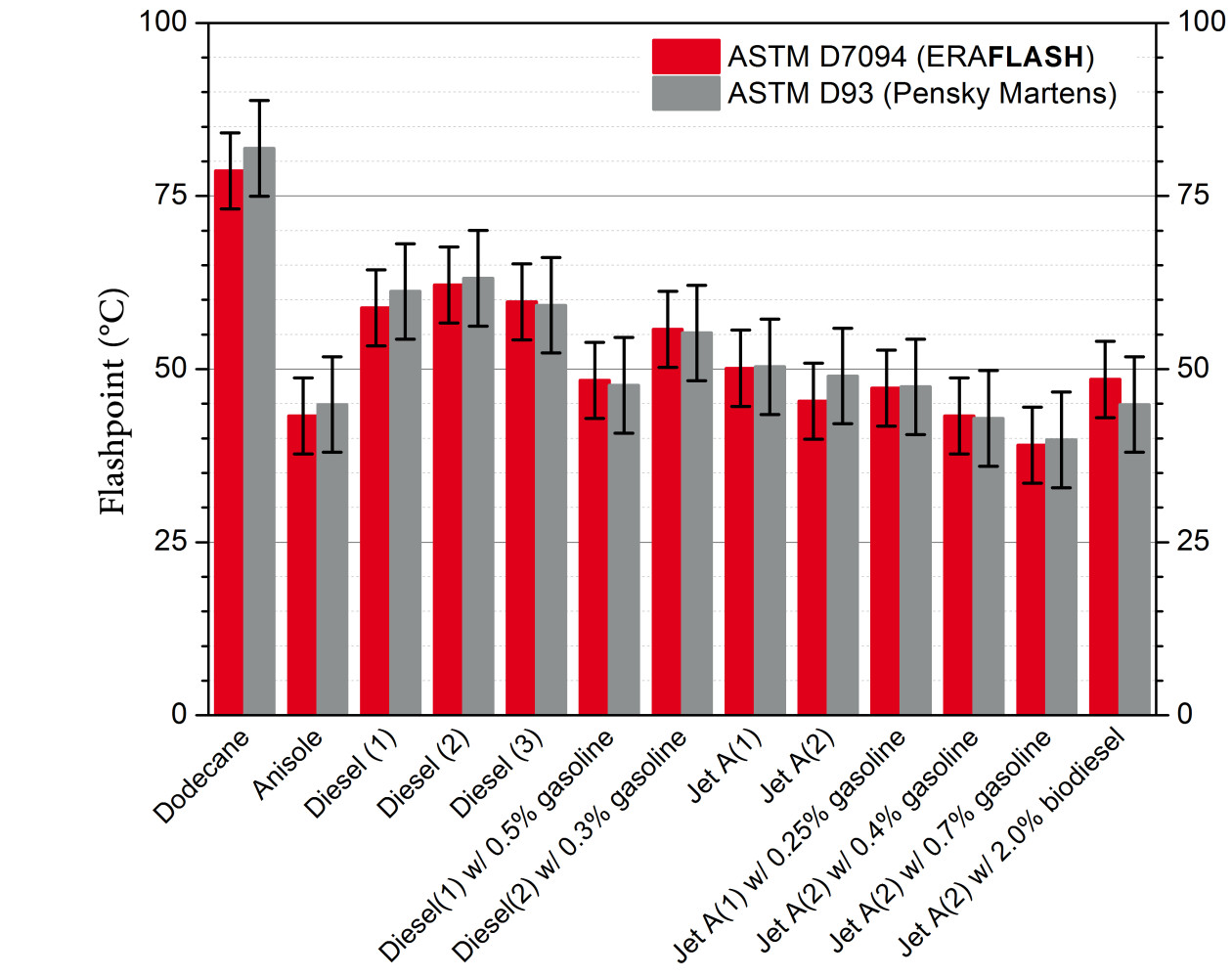

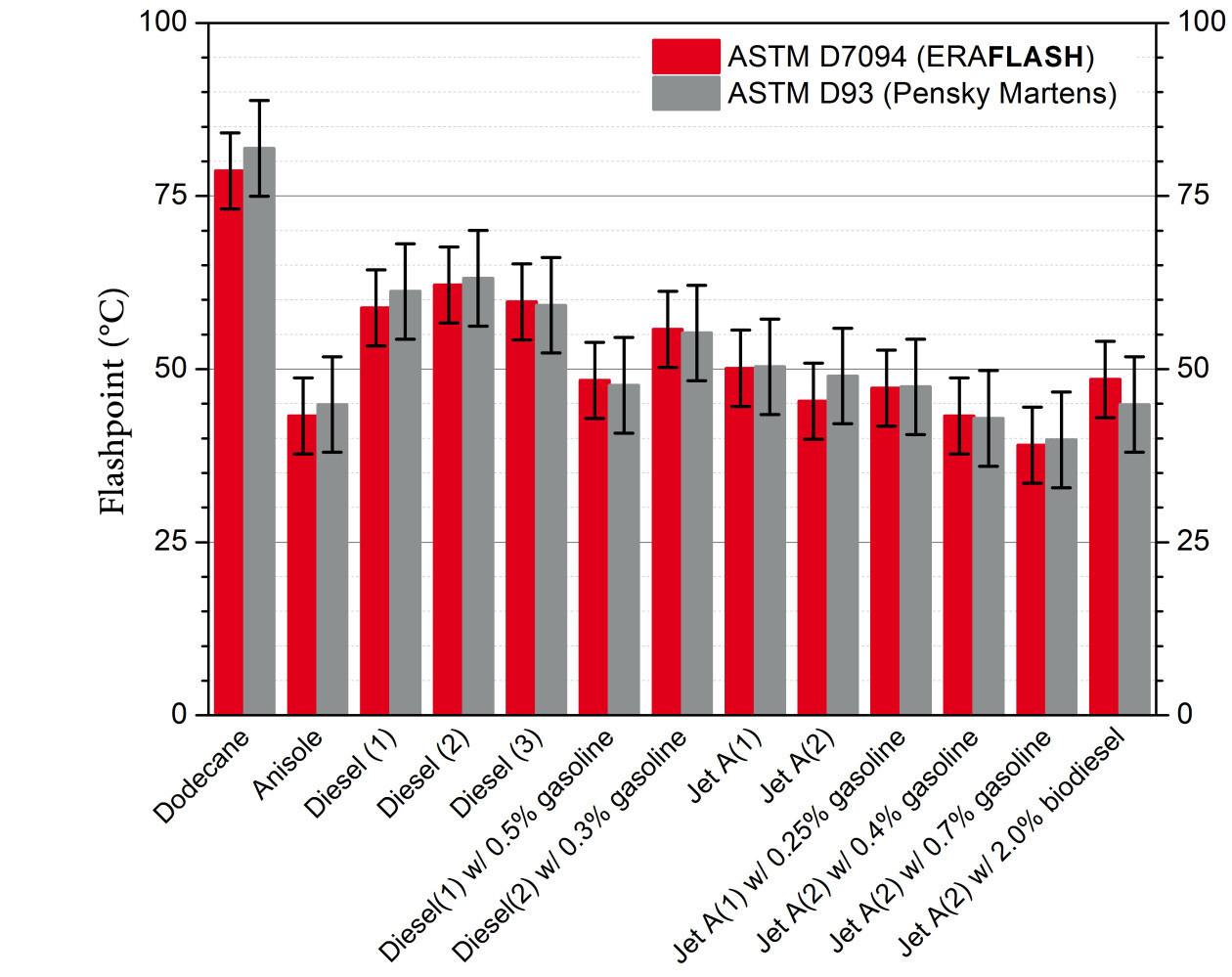

No Bias between ASTM D93 and ASTM D7094.

In 2004 an ASTM round robin test proofed that no statistical bias exits between ASTM D93 (Pensky Martens) and ASTM D7094 (modified continuously closed cup flash point, MCCCFP). This data led to the acceptance of ASTM D7094 for fuel specification testing in December 2013:

- Fuel oil (ASTM D396)

- Diesel fuel (ASTM D975)

- Gas turbine fuel oil (ASTM D2880)

- Kerosene (ASTM D3699)

- Diesel Fuel, Biodiesel Blend (ASTM D7467)

Additionally it was shown, that the repeatability and reproducibility of ASTM D93 for modern complex fuels is up to 50 % higher than stated in the method itself.

DENS4052 EXT: The all-new density option for ERAFLASH

The latest measuring option for ERAFLASH is eralytics innovative temperature-controlled, high-precision density meter module DENS4052 EXT, which is now available for the direct connection with ERAFLASH. With only 1.3 kg of weight, DENS4052 EXT is the lightest and smallest density meter on the market measuring in full compliance with ASTM D4052. This unique feature allows for a simultaneous density (ASTM D4052) and flash point measurement (ASTM D7094) for all types of samples.

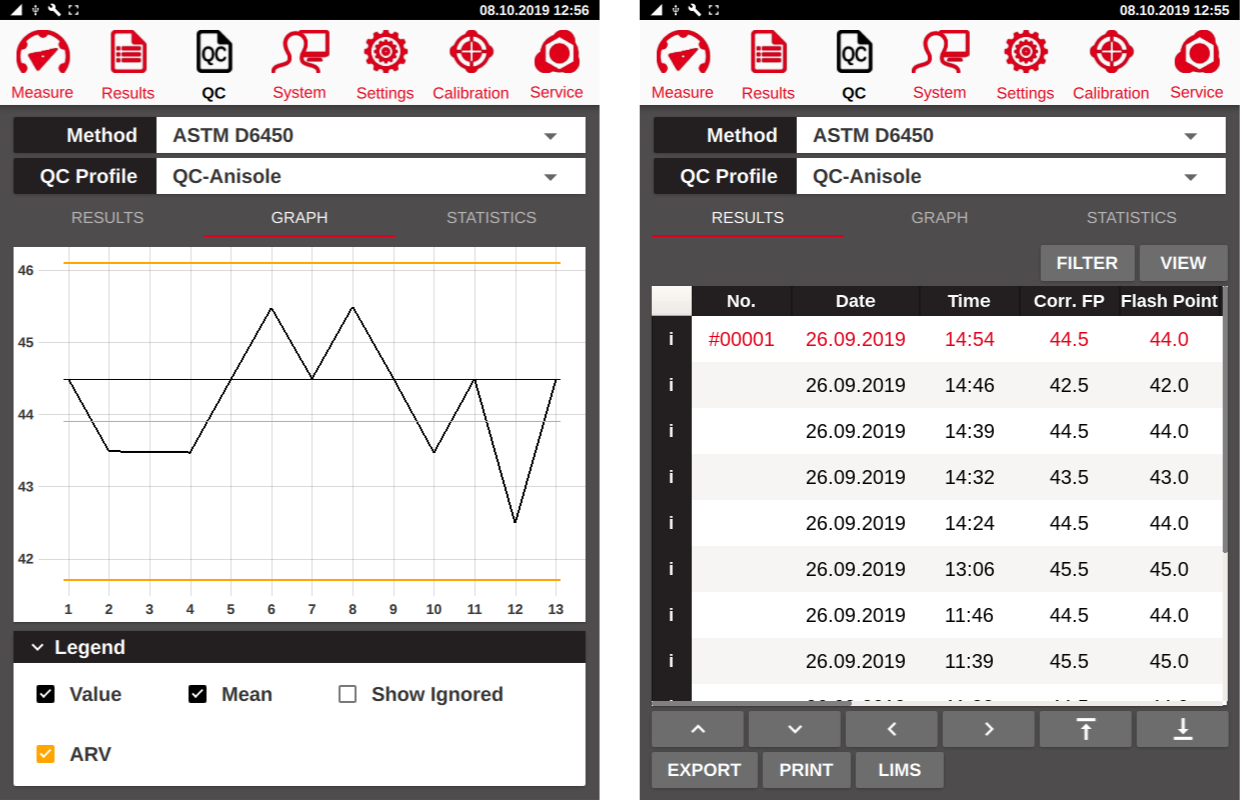

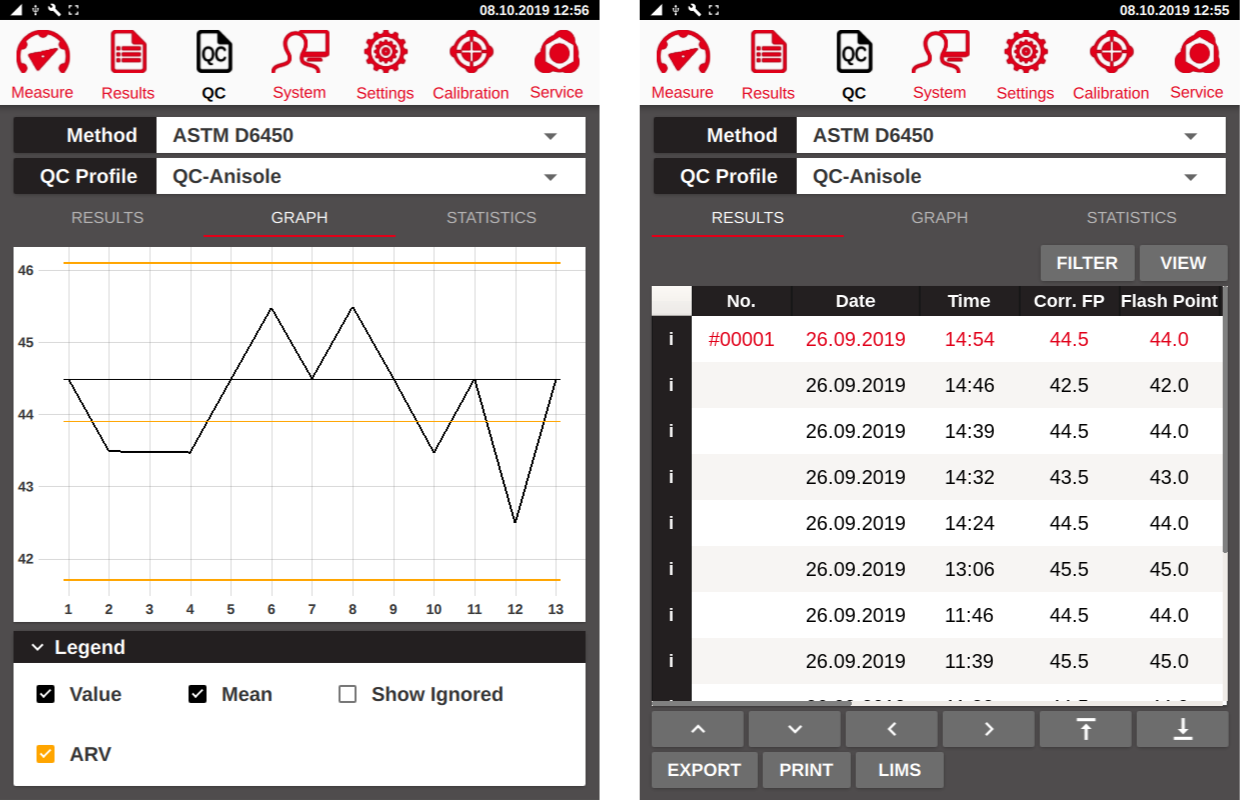

Quality Control Mode

For even more measurement comfort eralytics’ flash point testers offer a quality control (QC) mode right on the instrument. To perform efficient quality control, the user can set individual warning levels to each QC sample. If a sample is measured and the results fall outside these limits a warning is automatically displayed. Additionally, QC charts are available to easily identify long term drifts and perform statistical evaluations of results.

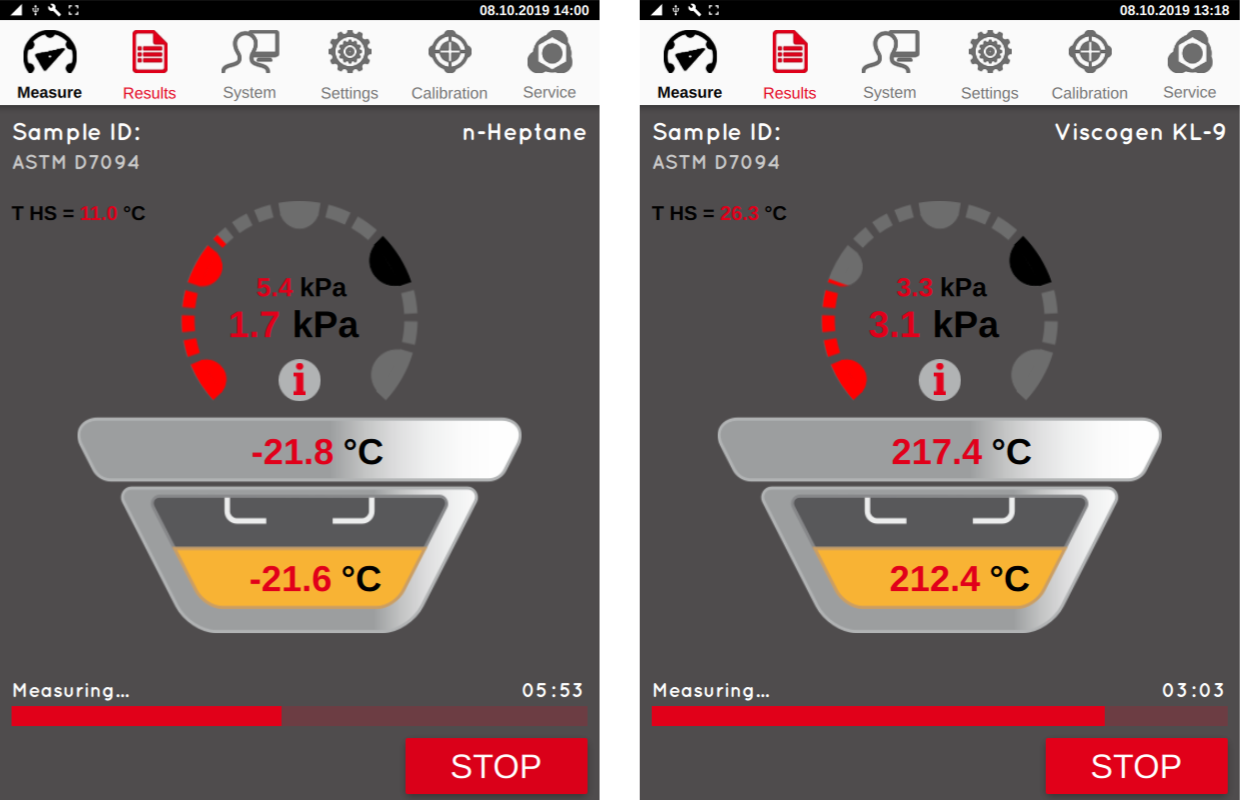

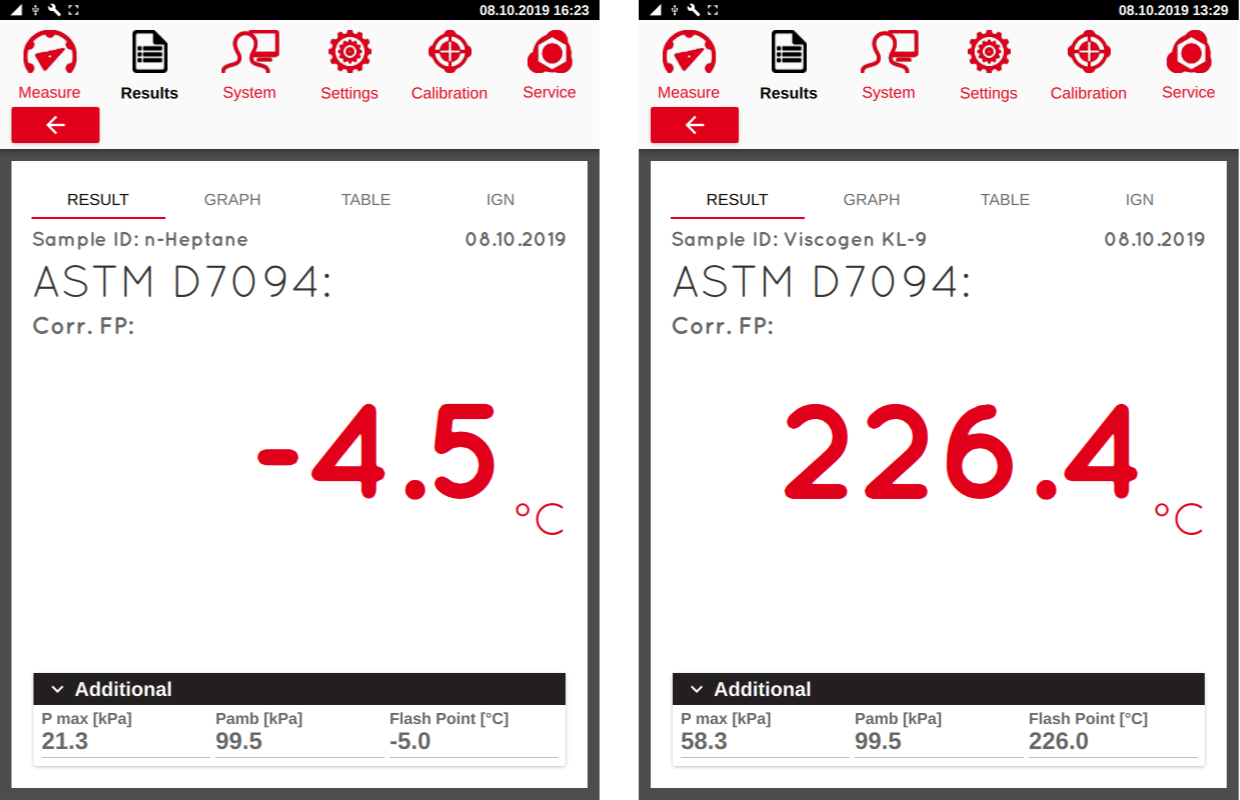

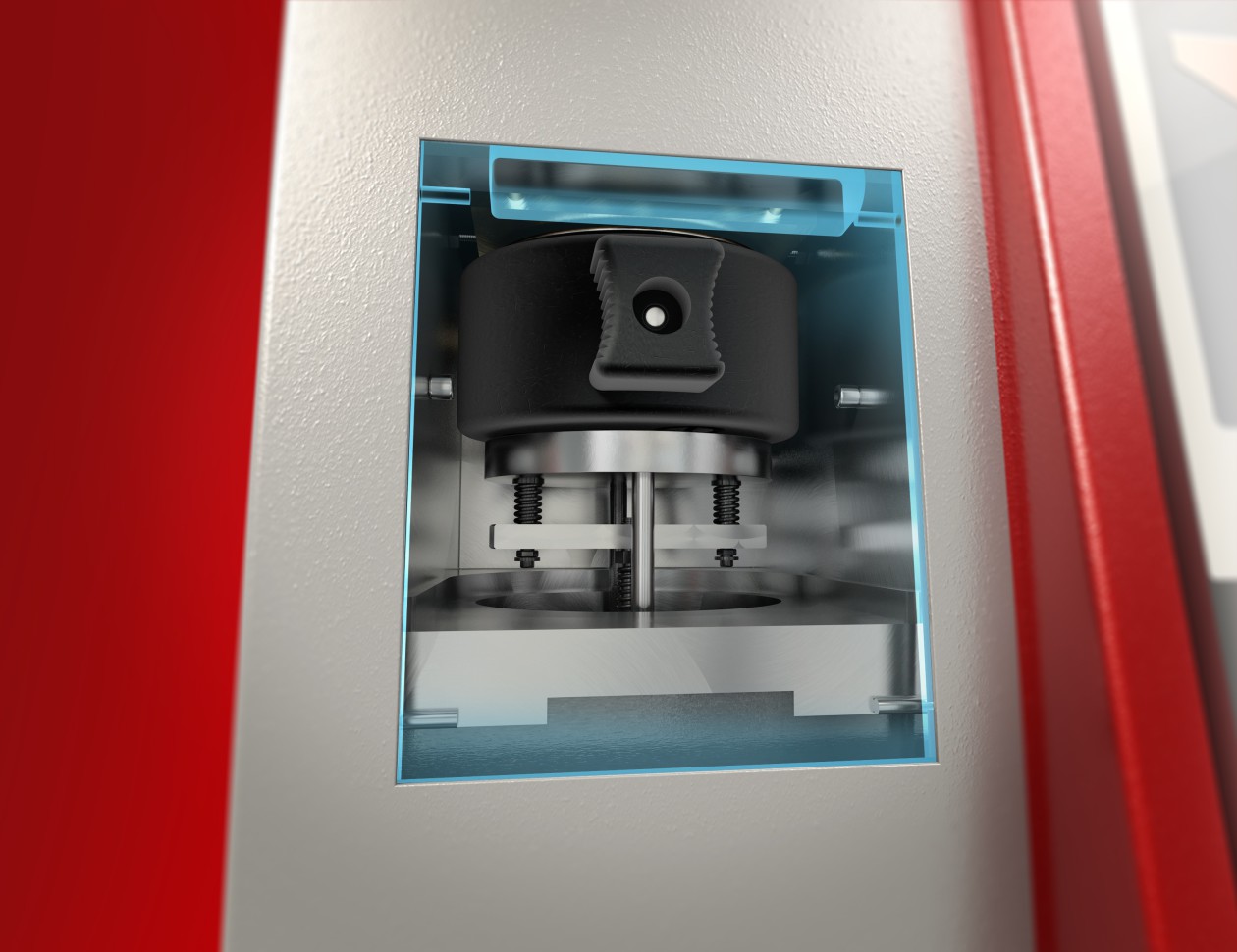

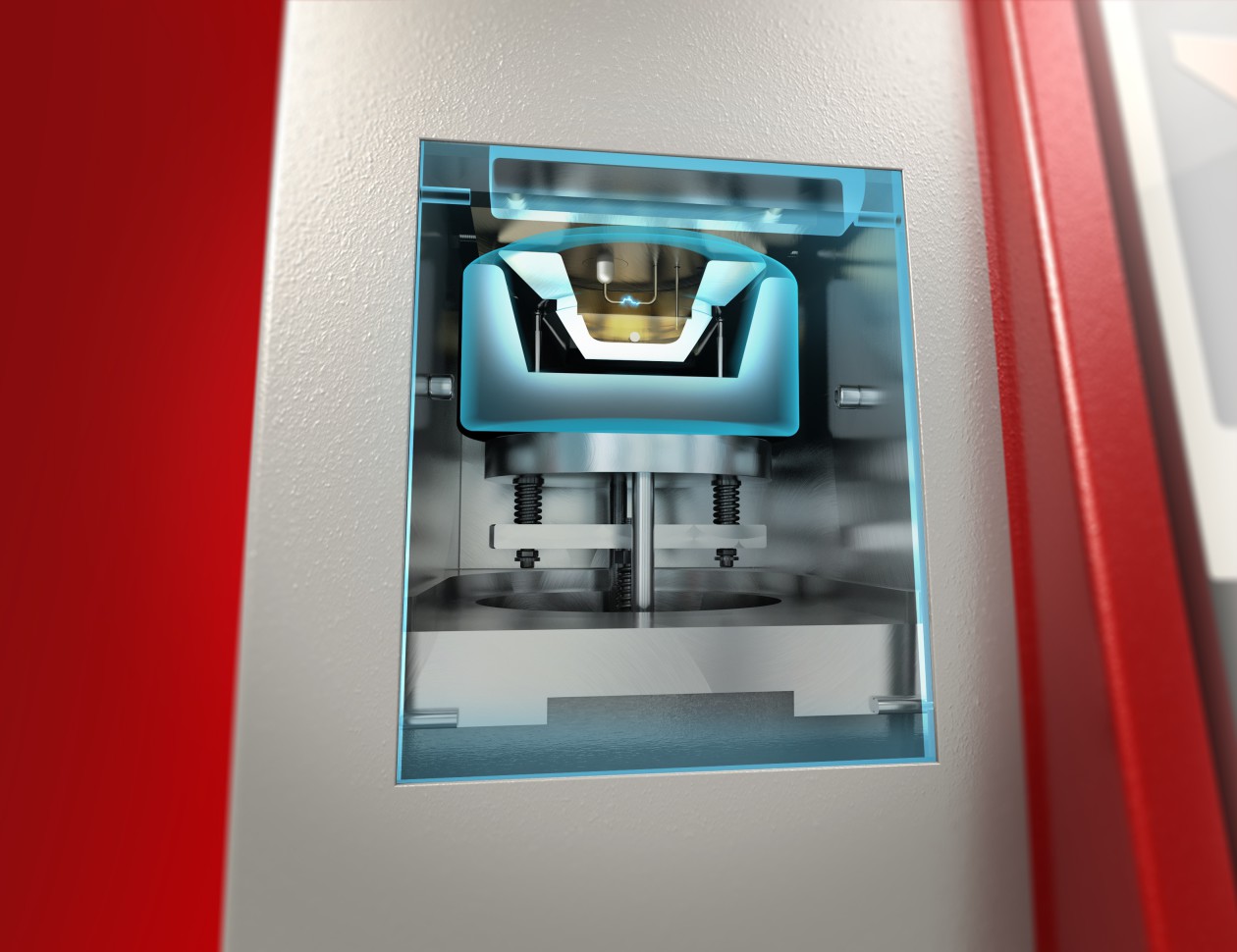

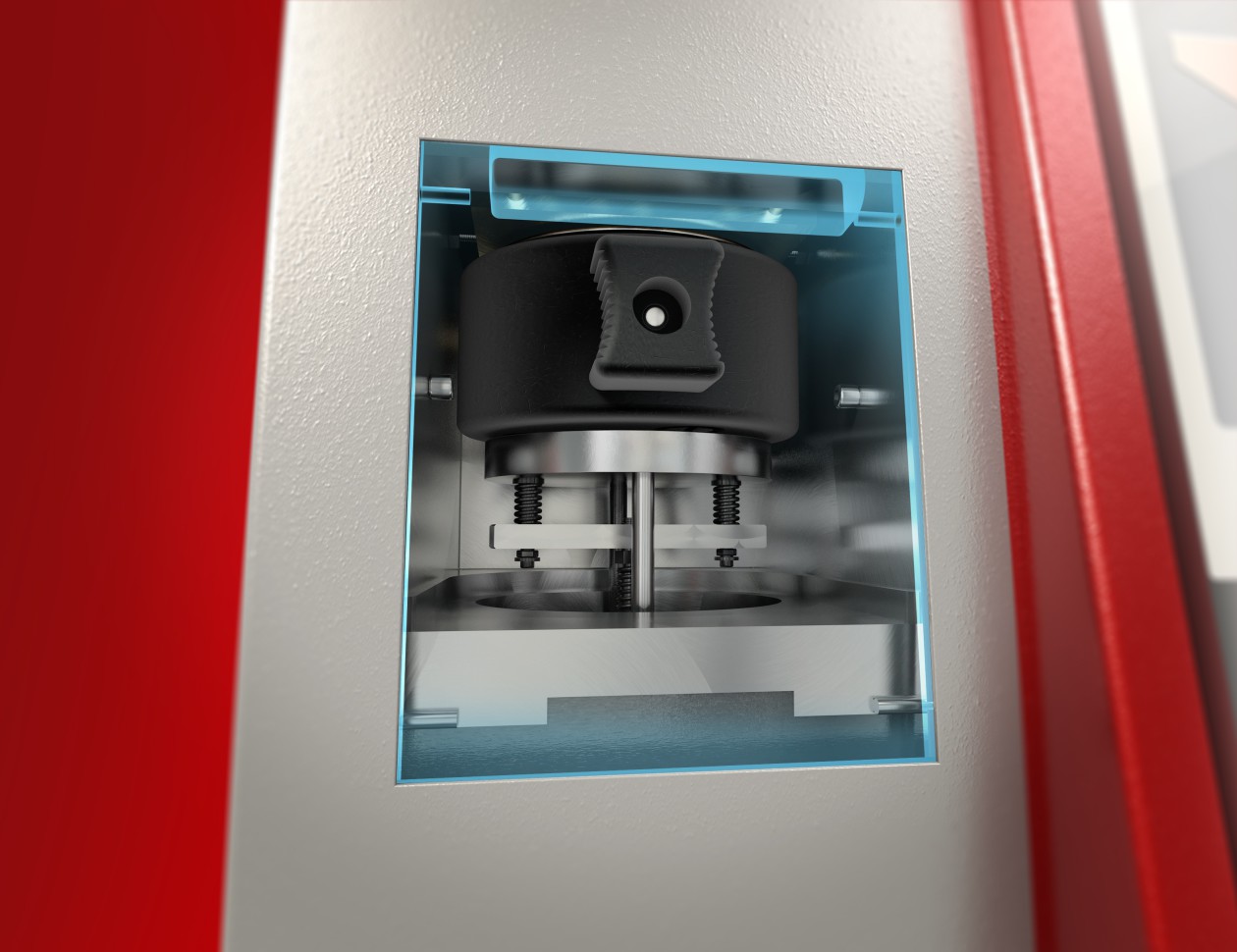

The Safe Side of Flash Point Testing

In contrast to Pensky Martens instruments the ERAFLASH flash point tester series does not use an open flame. Instead, 2 pins create an electric arc that is used to ignite the sample inside a closed chamber. Due to the small sample volume (1 ml or 2 ml) and the resulting low oxygen amount within the closed cup, the flame is automatically extinguished after ignition. The pressure increase in the closed cup following the ignition is used for the detection of the flash point. A pressure increase of ≥ 20 kPa is defined as a flash point by the method.

ASTM D6450, D7094 and IP 620 are inherently safe flash point methods eliminating any fire hazard from your lab.

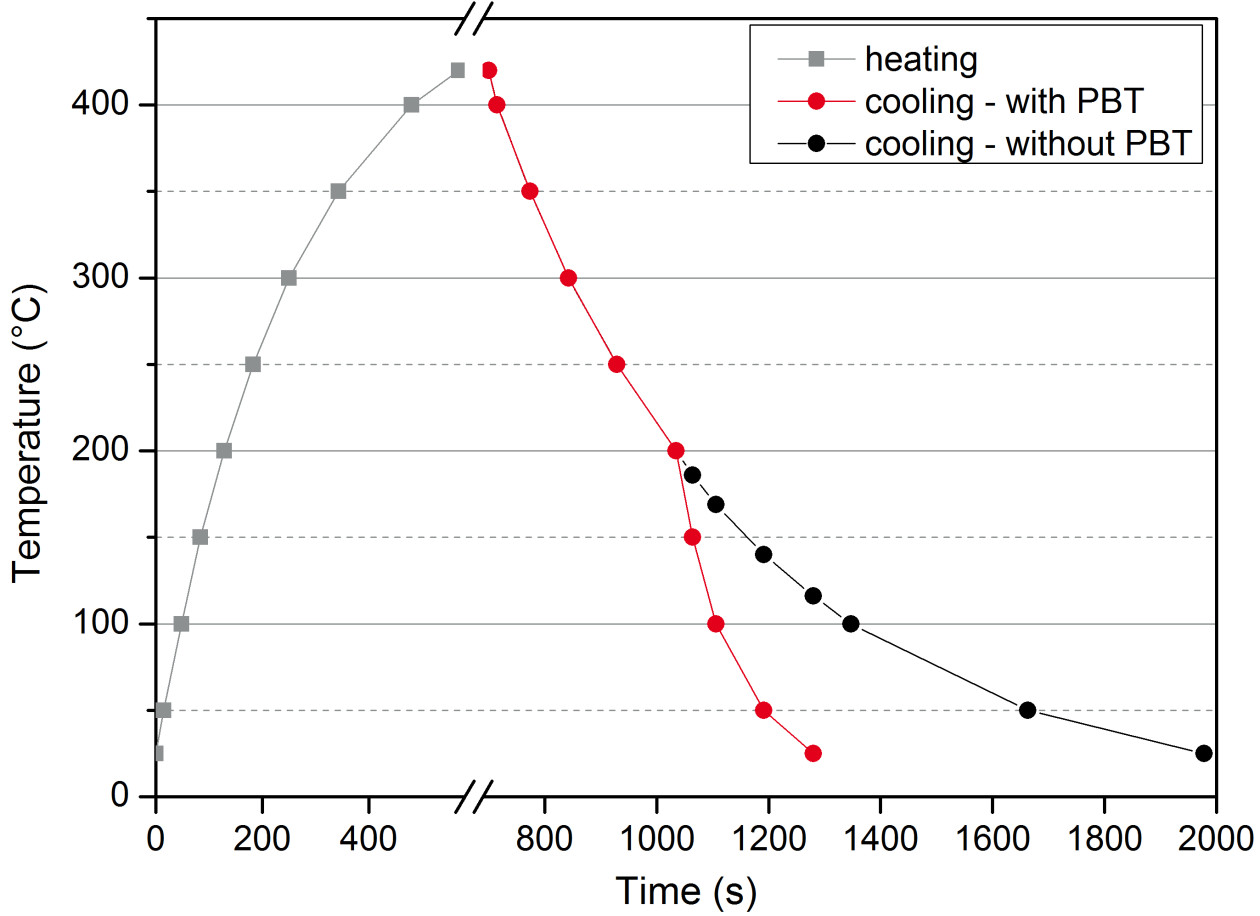

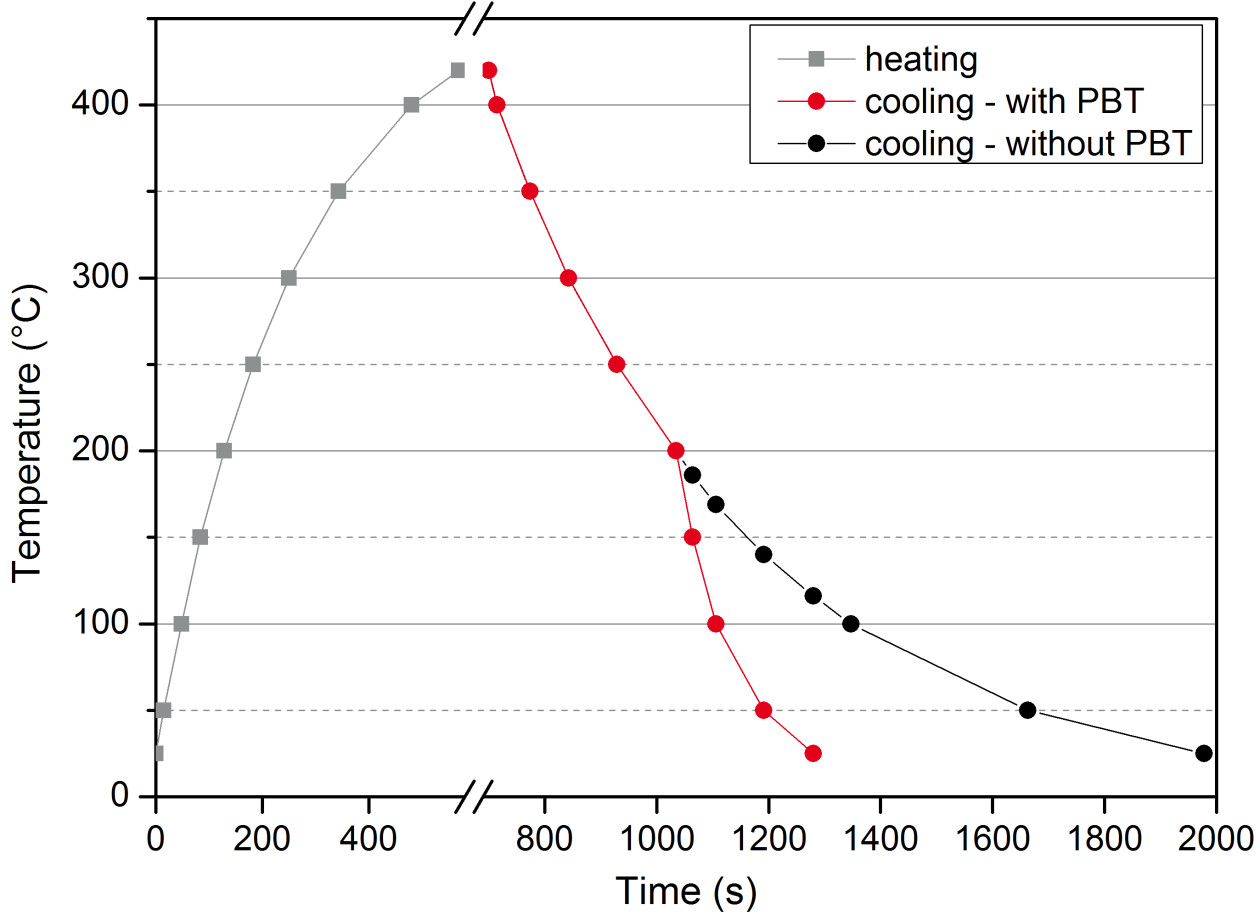

Unmatched Heating and Cooling Rates

The ERAFLASH flash point tester utilizes the patented Peltier Boost Technology™ (PBT) to significantly increase heating and cooling rates. With a sophisticated mechanism the Peltier elements are safeguarded from high temperatures during heat up and allows their use during cool down even at temperatures that would normally harm them. This eralytics’ innovation maximizes sample throughput by shortening the turnaround time of ERAFLASH.

Additionally PBT enables the ERAFLASH flash point tester series to cover a temperature range of -25 °C to 420 °C within a single instrument. The new ERAFLASH LT flash point tester was designed for faster flash point measurements at low temperatures. With its stacked Peltier design it reaches oven temperatures as low as -40 °C.

Application

ERAFLASH is the flash point testing solution for a wide variety of industries. It is used for specifying fuels, analyzing fresh and used lubricating oils, and bitumen testing. The small sample volume also renders it ideal for the more expensive samples such as flavors & fragrances, cosmetics, paints and varnishes or even hazardous waste.

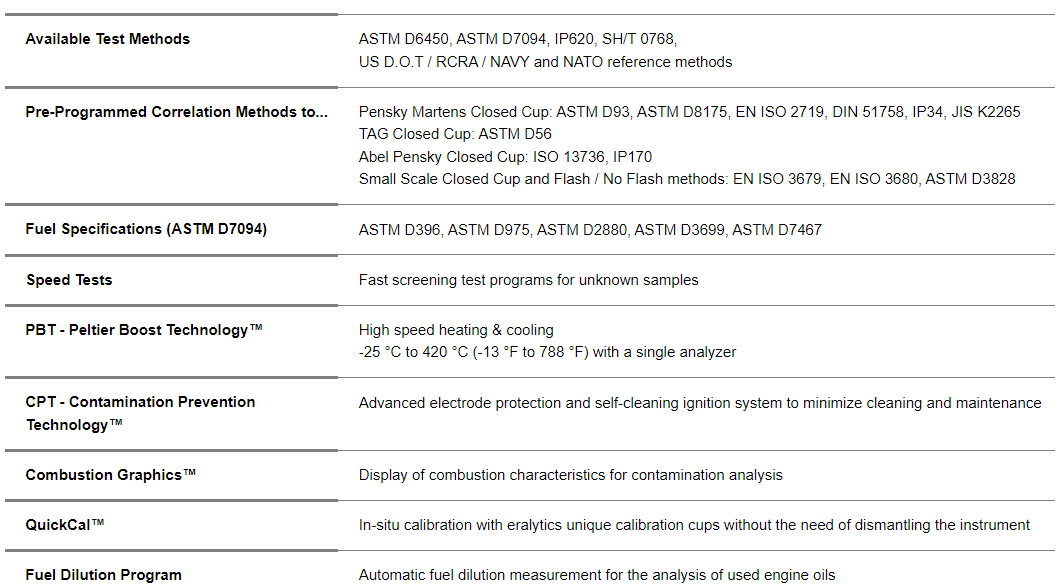

Specification