Console/Pilot Production Freeze Dryer/Lyophilizer

21 กุมภาพันธ์ 2567

ผู้ชม 119 ผู้ชม

Console/Pilot Production Freeze Dryer/Lyophilizer

Console/Pilot production freeze dryer is a small in-situ freeze-drying equipment. It is applied not only in pharmaceuticalpilot workshop and small batch production but also in food or medicinal freeze-drying process.

FEATURES

Situ freeze-drying technology is one of advanced international constructer design which avoid the contamination during materials transfer and realize the dry sublimation automatically. Pilot freeze dryer is with rack heating programmable function and memory freeze-drying curve which convenient users to get the freeze-drying production technology.

It is divided into standard type and gland type.

Reliable Performance

World famous compressor (SECOP) , high performance. lubricating oil with Sole design ensure the compressor work stable in high and low environment which enhance the compressor life. World famous dry-filter to avoid moisture and Impurity went into refrigerant system.

·The rack is cooled and heated through Silicone oil. The temperature accuracy is ≤1 ℃,the refrigerant and

heating are uniformity.

·In-situ freeze-drying design, avoid the contamination during material transfer. High transparent organic glass

in Drying chamber helps users to observe materials changes.

·Cold trap and drying chamber are separately designed which is with high moisture capture and fast dry time.

·Chamber is made of stainless steel, anti-corrosion and easy cleaning. Each rack is with temperature sensor and monitor the materials temperature changes in each rack.

·Square racks easy to cleaning

·With gas valve, can inject dry inert gas.

Humanized Design

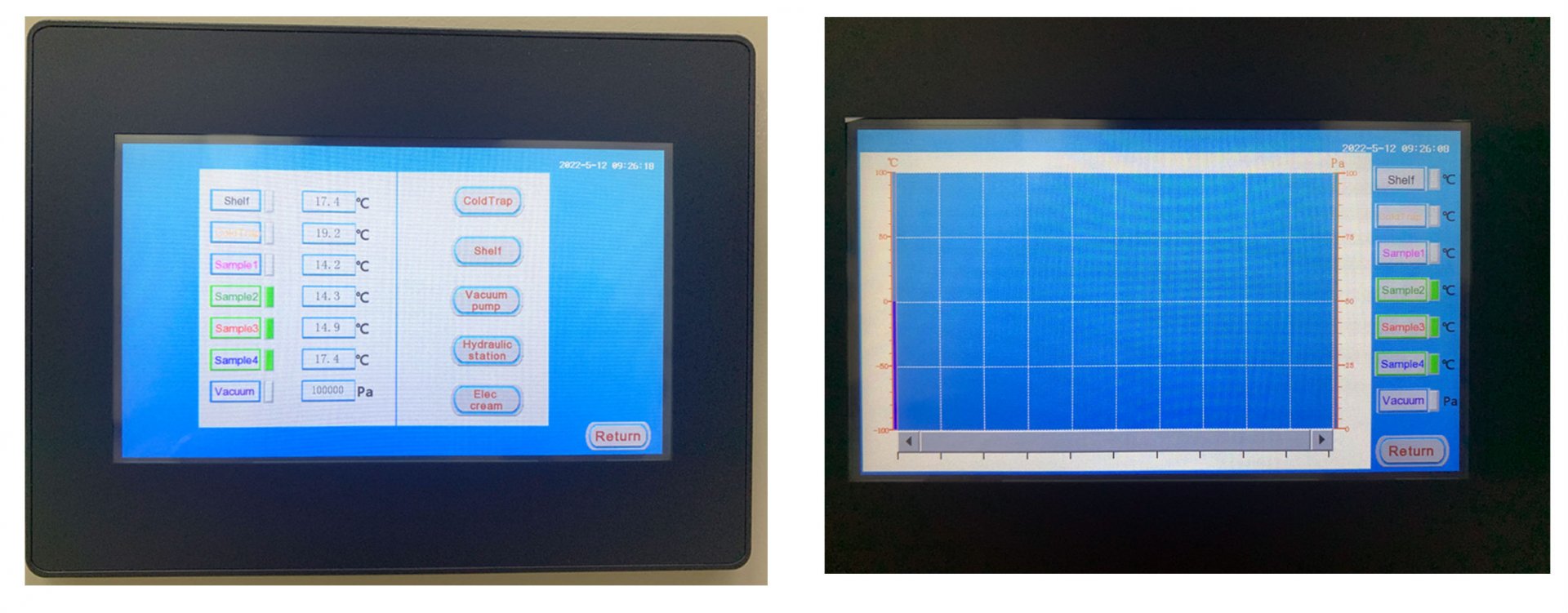

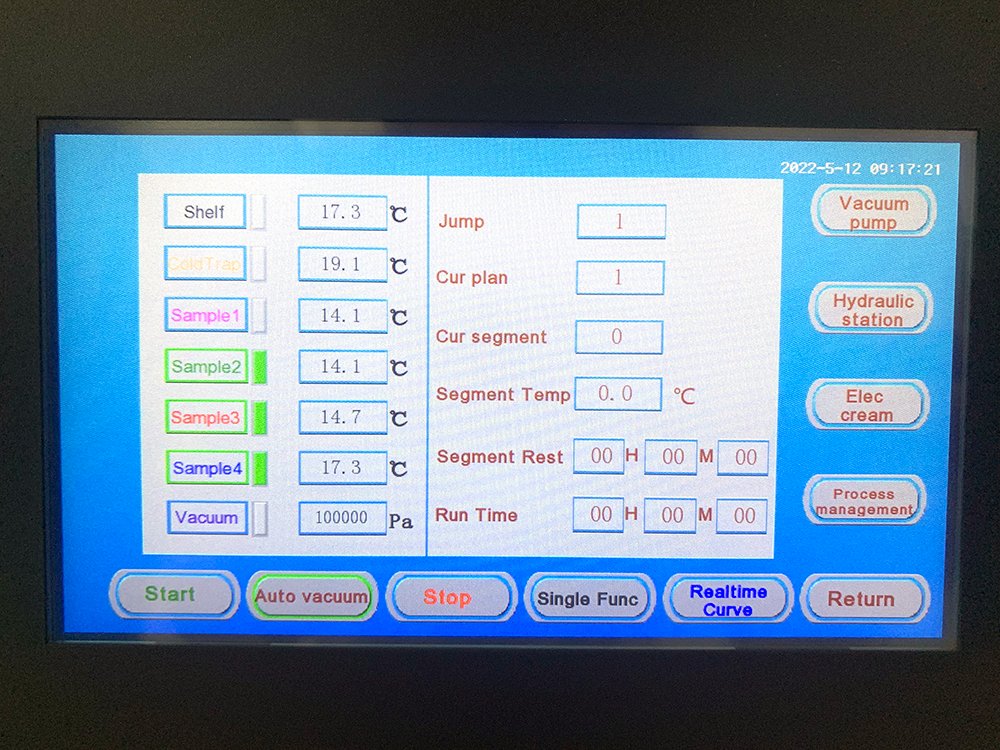

·7”colorful touch panel, can digital and curve display the real time status and historical data.

·Large FAT32 files system storage can store all data for more than 1 month.

·USB interface can download the freeze-drying data to U disk

·Rack temperature can adjustable,controllable which helps to search for freeze-drying technology. It is two types manual and automatic type.

·The Automatic process can setting 36 programs, each program can set 40 temperature range, it can meet different requirements on freeze-drying process.

·Automatic frost

·Optional Eutectic point test function helps users to control materials’ sublimation point

·Optional Freeze drying flask

SPECIFICATIONS

| Model | INOFD-20S | INOFD-30T | INOFD-50S | INOFD-50T | INOFD-100S | INOFD-100T | INOFD-200S | INOFD-200T |

| Type | Standard | Top-press | Standard | Top-press | Standard | Top-press | Standard | Top-press |

| Shelf temp(℃) | -50 ~ 70 | -50 ~ 70 | -50 ~ 70 | -50 ~ 70 | -50 ~ 70 | -50 ~ 70 | 50 ~ 70 | 50 ~ 70 |

| Final condenser temp (℃) | -80 | -80 | -80 | -80 | -80 | -80 | -80 | -80 |

| Vacuum Degree (Pa) | <10 | <10 | <10 | <10 | <10 | <10 | <10 | <10 |

| Freeze drying area (m2) | 0.24 | 0.3 | 0.5 | 1 | 2 | |||

| Condenser capacity (Kg/24h) | 6.5 | 10 | 15 | 30 | ||||

| Shelf specification (L*W*H mm) | 300*400*15 | 295*335*15 | 360*476*20 | 360*480*15 | 600*480*15 | 500*900*15 | ||

| Qty of shelf | 2 | 3 | 4 | 4 | 6 | 4 | 6 | 6 |

| Distance between shelves(mm) | 80 | 70 | 95 | 80 | 80 | 100 | ||

| Liquid material loading capacity (L) | 4.5 | 4 | 10 | 8 | 15 | 30 | ||

| Temperature uniformity (℃) | ±1 | ±1 | ±1 | ±1 | ±1 | ±1 | ±1 | ±1 |

| Defrost funINOion | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| USB Interface | Y | Y | Y | Y | 。 | Y | Y | Y |

| Control System | Microprocessor, touch screen | Microprocessor, touch screen | Microprocessor, touch screen | Microprocessor, touch screen | ||||

| Penicillin bottle Φ22 | 760 | 805 | 1408 | 1056 | 2016 | 2016 | 4100 | 4100 |

| Penicillin bottle Φ16 | 940 | 1550 | 2728 | 2046 | 3960 | 3960 | 7800 | 7800 |

| Penicillin bottle Φ12 | 2120 | 2800 | 4920 | 3690 | 7200 | 7200 | 14400 | 14400 |

| Power supply (V/Hz) | 220V/50Hz,60Hz | 220V/50Hz,60Hz 380V/50Hz,60Hz |

220V/50Hz,60Hz 380V/50Hz,60Hz |

380V/50Hz,60Hz | ||||

| Exterior dimension (WxDxH mm) | 1200*750*1250 | 1200*750*1600 | 1200*850*1500 | 1200*850*1850 | 1500*850*1600 | 1500*850*1950 | 2100*850*1800 | 2100*850*2100 |

ACCESSORIES:

1. Optional Vacuum Pump

| Model | Ultimate Pressure (Pa) |

Pumping Speed (L/S) |

Rotary | Inlet Diam | Motor | Weight | Dimensions | Benchmark model |

| INOVP-1 | 6×10-2 | 1 | 1440 | Φ16 | 0.25 | 19 | 470×140×235 | RV3 |

| INOVP-2 | 6×10-2 | 2 | 1440 | Φ25 | 0.37 | 27 | 480×140×255 | RV5 |

| INOVP-4 | 6×10-2 | 4 | 1440 | Φ25 | 0.55 | 30 | 510×140×255 | RV12 |

2. Optional N2 generator

| NO. | ITEM | Description |

| 1 | Fluid | Compressed air after non-corrosive purification |

| 2 | Working Principle | Variable Pressure Adsorption |

| 3 | Inlet air flow | Std.150L/min |

| 4 | Inlet air pressure | Std.8 bar | Min 0.7 bar Max:0.85 bar |

| 5 | Inlet air temperature | Std.25 ℃ | Max:35℃ |

| 6 | Working environment temperature | Std.32 ℃ |Min 0℃ Max:45℃ |

| 7 | Pressure loss at full load | Std.0.2 bar |

| 8 | Outlet nitrogen temperature | +5~25℃ |

| 9 | Outlet nitrogen dew point | -30℃ |

| 10 | Outlet nitrogen pressure | 0.05-0.6Mpa adjustable |

| 11 | Export nitrogen purity | ≥95% |

| 12 | Outlet nitrogen flow | ≥3m³/h |

| 13 | Air Inlet | DN15 |

| 14 | Nitrogen outlet | DN15 |

| 15 | Power | 220V 50Hz | 2500W 2 phase 3 wire |

| 16 | Net weight | 100kg |

| 17 | Dimension (H*W*D) | 1300×600×550 |

| 18 | Structure form | Case-type |

| 19 | Noise level | 1 meter from the equipment, noise less than 50 decibels |

3. Optional Booster Pump

| Exhaust rate | 50Hz | 500m³/h (8330L/min) |

| 60Hz | 600m³/h (10000L/min) | |

| Suction pressure | 50Hz | 1.3x10³Pa |

| 60Hz | 1.1x10³Pa | |

| The maximum allowable pressure difference (discharge pressure - suction pressure) |

50Hz | 7.3x10³Pa |

| 60Hz | 6.0x10³Pa | |

| Ultimate pressure | 4.0x10-1Pa | |

| Motor | 2.2KW | |

| Oil required | 1.6L | |

| Cooling water | Flow | 2L/min |

| Cold water pressure | 1x10-1Mpa | |

| Water temperature | 5-30°C | |

| Weight | 79.5kg | |

| Suction port | VG80 | |

| Exhaust vent | VF80 |