AQUA 40.00 Vario - Water content of all types of samples

27 ธันวาคม 2566

ผู้ชม 206 ผู้ชม

Water determination in all types of samples

Flexible, cost-efficient and easy handling without sample preparation

|

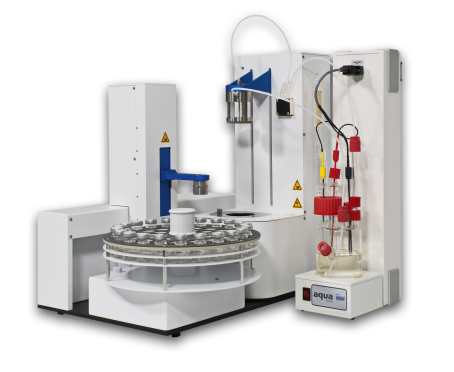

| AQUA 40.00 Vario PLUS (with autosampler) |

|

| AQUA 40.00 Vario (manual version) |

|

| SWOP Box - universal reagent exchange module |

Water content of all types of samples

- Closed-loop circulation of extraction gas

- Manual and automatic version available

- Easy to adapt to different vial sizes

The AQUA 40.00 Vario combines the Karl Fischer Titration with the headspace technique. This offers a wide range of interesting applications to determine moisture in solid and pasty samples, oils and viscous compounds.

The sample preparation takes place using the dynamic headspace technique. The sample - in a closed vial - is placed into the headspace oven and tempered.

A closed-loop gas circulation with dry carrier gas flows across the sample and transports the extracted water completely into the measuring cell, where the analysis is carried out by titration according to the Karl Fischer method.

It does not require time-consuming sample preparation:

- Weigh out the sample into the headspace vial and close it

- Place the vial in the device (manually or automatically)

- Prepare the measurement and start it

Distinction of binding forms

Temperature-controlled heating procedure, e. g. with temperature program, can be defined individually by the user. Such a temperature program reveals in which way the water in question is bonded to the sample substance. You can distinguish between chemically bonded water of crystallization and adsorbed surface water.

Closed-loop gas circulation

The system has the unique advantage of circulating the extraction gas in a closed loop. Any additional gas drying is not necessary. The internal carrier gas for the extraction is continually titrated to dryness within the closed loop. The total dryness of the gas enhances the moisture release from the sample. Sensitive samples can be heated out very gently. All these advantages result in reducing reagent consumption considerably.

Applications

- Pharmaceutical products

- Biological substances

- Plastics

- Hygroscopic compounds

- Freeze-dried products, e. g. lyophilized cultures

- Oils and lubricants, creams, pastes

- Viscous materials (bitumen, tar, sludges)

- Powder and pellets

- Food

- Petrochemicals

Advantages

- Reduced reagent consumption

- Additional gas drying is not required due to closed-loop circulation of extraction gas

- No evaporation of methanol from reagents

- Temperature programmed procedures

- Short measuring times of complex samples

- Stand-by titration for automated conditioning and easy blank tests

- Suitable for 2 R – 50 R vials

- Easy automation with autosampler

- Software complies with requirements of FDA to 21 CFR Part 11 (Software with user-specific access, routine methods for individual and definable user levels, profound documentation and archiving of all measured data)

- Priorized express samples can set individually by user

- Automatic identification of interchangeable oven and sample plate of the autosampler

Technical specifications

| Sample vial: | headspace vials (size 2 R – 50 R) |

| Measuring range: | 1 µg – 100 mg, absolute |

| Resolution: | 0.1 µg |

| Reproducibility: | ± 3 µg for 10 … 1000 µg 3 % for > 1 mg |

| Temperature range: | 35 °C ... 300 °C (isothermal or temperature programmed) |

| Power supply: | 230 V, 50/60 Hz; 115 V, 50/60 Hz |

| Power input: | 250 W |

| Dimensions/Weight: | Manual version: 300 x 450 x 240 mm (W x H x D)/7 kg Autosampler version: 420 x 450 x 460 mm (W x H x D)/17 kg |

| Device control: | PC software (PC not included in the scope of delivery) |