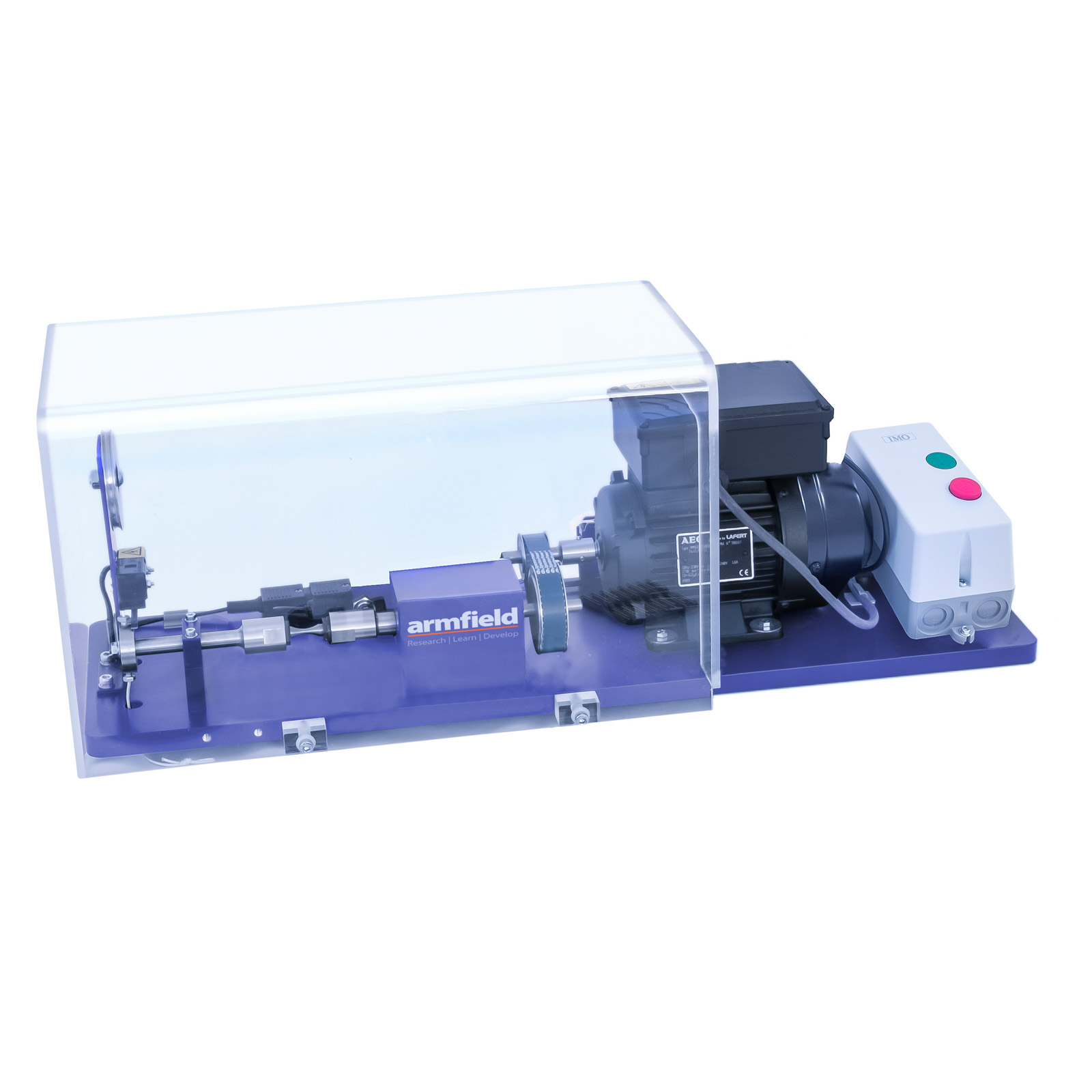

Rotating Fatigue Machine

20 เมษายน 2566

ผู้ชม 171 ผู้ชม

DESCRIPTION

The SV800 rotating fatigue machine has been designed to introduce students to the effects of material fatigue using a sinusoidal variation of bending stress.

A 2800rpm motor rotates a specimen through a gear and pulley arrangement between 5600 or 1400 rpm. The specimens are held within ‘keyless’ chucks and loaded using a cantilever arrangement, with the load being applied through a screw jack mechanism with integral cantilever load cell.

A digital interface displays the applied force and revolution count of the specimen. Both values can be reset and zeroed (tared) prior to the testing commencing. When specimen failure occurs, a micro switch stops the motor and the cycles to failure are registered on the digital display. The count remains when the motor is not running. A safety guard shields all rotating parts.

The AIU Armfield interface unit allows a host computer (not supplied) to be connected to the SV800. The software supplied allows the capture and reviewing of data.

EXPERIMENTAL CONTENT

- To make an introductory study of fatigue using a Wohler rotating fatigue apparatus, including the time to failure caused by various stress levels and materials

- Introducing students to S-N curves

- Material specification on fatigue limits

- Specimen geometry on fatigue limit

TECHNICAL SPECIFICATIONS

- Motor speeds: 5600 or 1400rpm

- Motor speed: 2800rpm nominal

- On-board starter box

- Timing pulley and belt drive system: 20t and 40t

- 10 x Standard specimens: Ø4mm neck diameter x 65(L) mm, steel

- Cantilever loading arrangement

- Clear safety guard

- Safety: Motor will remain inactive with safety guard removed

FEATURES & BENEFITS

- Fatigue testing based on Wohler

- Fully guarded system

- Variable speed

- Automatic motor cut-off following specimen fracture

- Digital force sensor

- Digital interface and software

- Keyless chucks

- Set of specimens supplied with spares optionally available