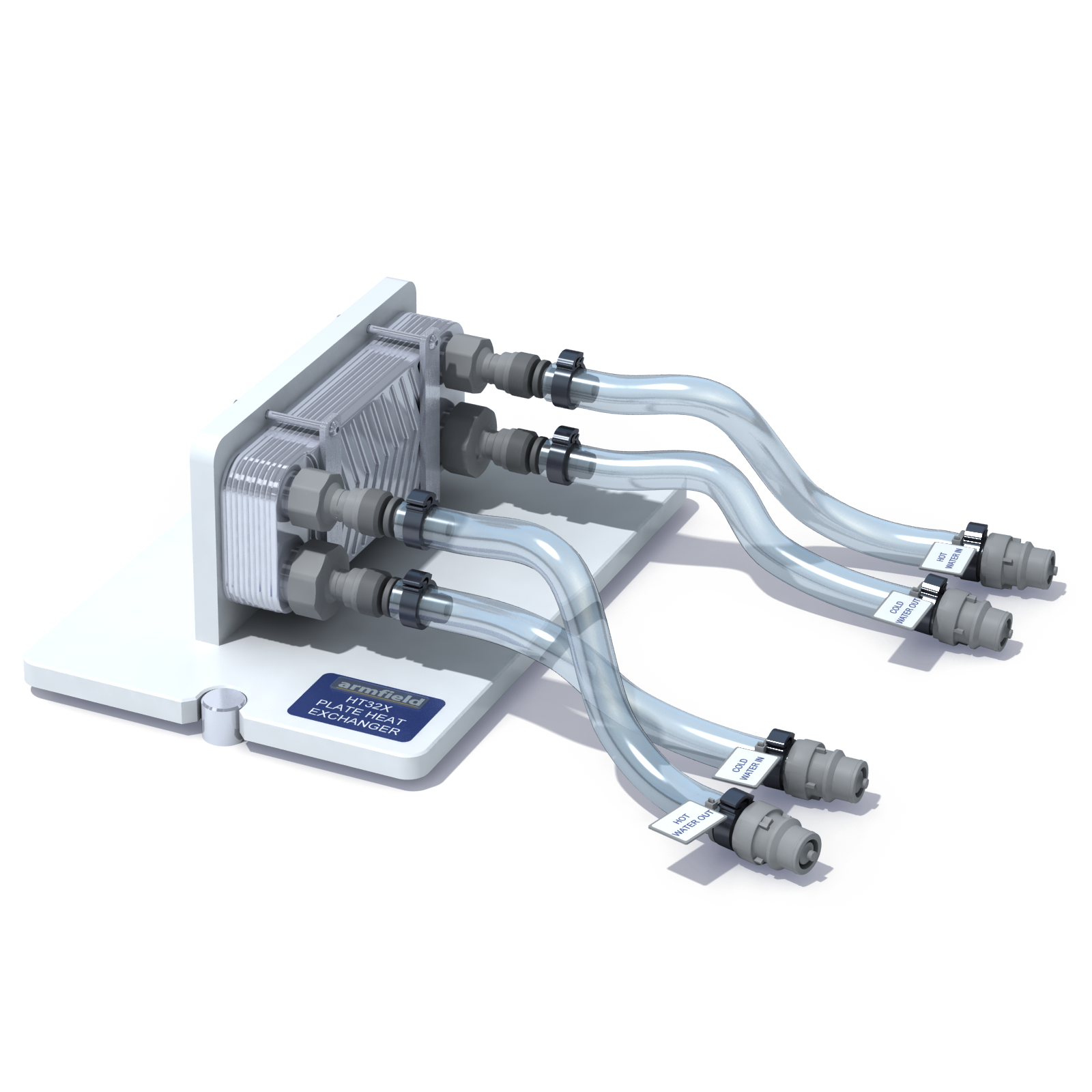

Plate Heat Exchanger

20 เมษายน 2566

ผู้ชม 425 ผู้ชม

DESCRIPTION

The plate heat exchanger is extremely versatile and commonly used in the food and chemical processing industries.

The HT32X has a single heating section configured for multi-pass operation with passes in series.

It comprises 10 individual plates. When being assembled, each second plate is rotated by 180°, thus forming two separately rotated flow chambers by the means of which the mediums being involved in the heat transfer are conducted in counter flow.

TECHNICAL SPECIFICATIONS

As suggested by its name, the plate heat exchanger consists of wave-shaped panels that are assembled in a unique way. There are interspaces between the plates.

The plates are manufactured from thin sheets of stainless steel, embossed with corrugations that promote turbulent mixing even at low Reynolds numbers. This turbulent mixing has the advantages of creating very high heat transfer coefficients and reduce fouling that may occur.

Hot and cold fluid flows may be configured for either cocurrent or countercurrent operation.

Plate details:

Plate overall dimensions: 191mm x 73mm

Effective heat transfer area: 0.12m2

Projected heat transmission area: 0.015m2

Number of plates: 10

Conductive panel (Plate thickness): 0.26mm

Distance between plates: 2.1mm

Material: Stainless steel, copper

FEATURES & BENEFITS

- A small scale plate heat exchanger system for use with an Armfield Computer Controlled Heat Exchange Service Unit to teach the fundamental concepts of heat exchangers

- Comprises a number of stainless steel plates, each with a pressed chevron pattern, soldered with copper using a vacuum soldering procedure

- A comprehensive instruction manual is included