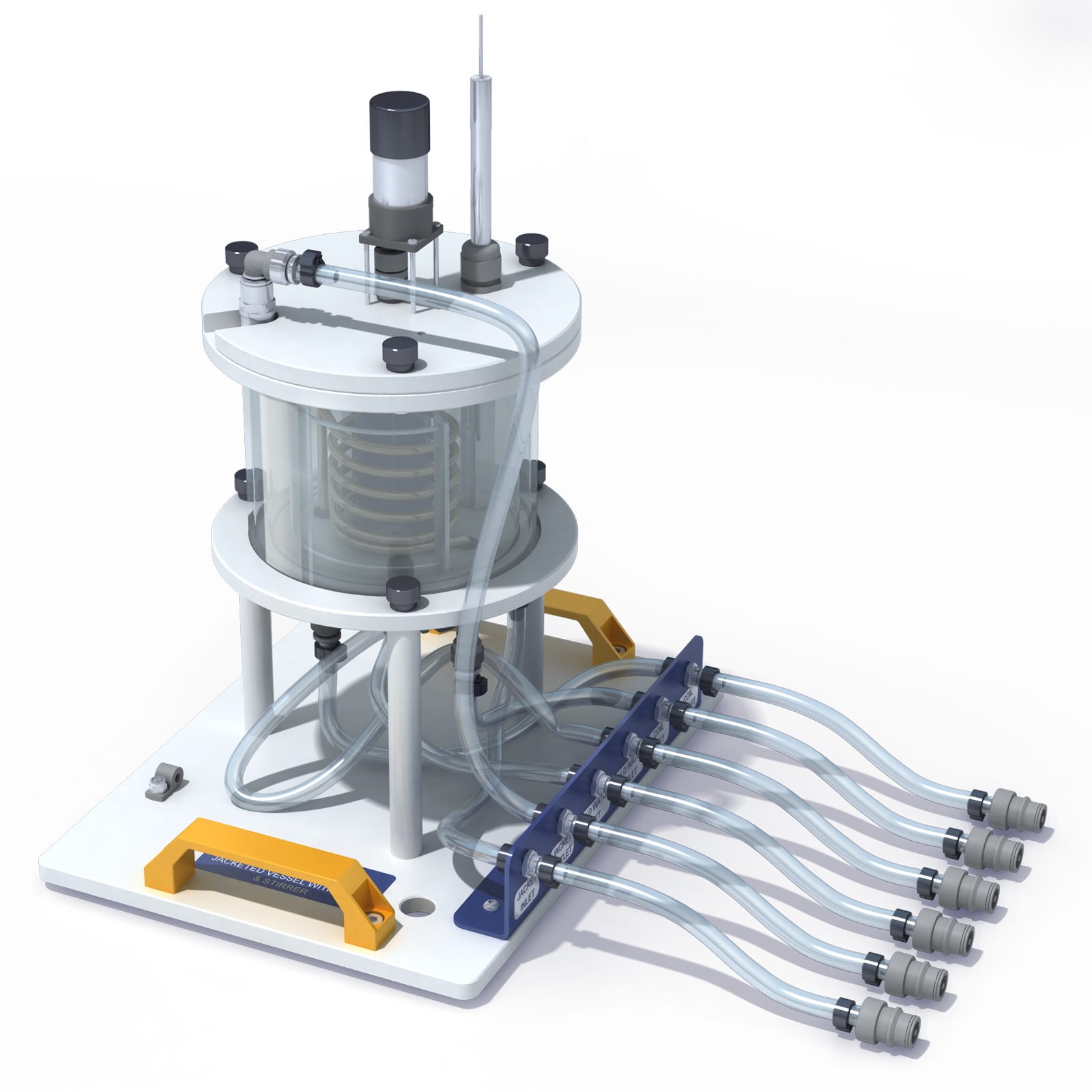

Jacketed Vessel With Coil And Stirrer

หมวดหมู่สินค้า: HT SERIES - COMPUTER CONTROLLED HEAT EXCHANGE / HEAT TRANSFER

รหัส : HT34X

The characteristics of the heat transfer using an external jacket or internal coil can be demonstrated together with the effect of stirring the vessel contents.

20 เมษายน 2566

ผู้ชม 270 ผู้ชม

DESCRIPTION

Vessel Heating or cooling of a process liquid in a tank, either batchwise or with continuous product feed, is common practice throughout industry.

The characteristics of the heat transfer using an external jacket or internal coil can be demonstrated together with the effect of stirring the vessel contents.

TECHNICAL SPECIFICATIONS

The accessory consists of a jacketed vessel with the following features:

- The vessel consists of a stainless steel wall with PVC base and clear acrylic top. A glass outer jacket allows the wall of the vessel to be surrounded with hot fluid for indirect heating from the outside. Alternatively, a stainless steel coil inside the vessel allows the cold fluid contained within the vessel to be indirectly heated from inside.

- The vessel incorporates a variable speed stirrer and baffle arrangement to provide thorough mixing of the vessel contents when required.

- An adjustable overflow enables the volume of liquid inside the vessel to be varied with a maximum capacity of two litres and a minimum of one litre.

- The vessel can be operated batchwise by simply filling to the overflow or with continuous feed of cold liquid to the base of the vessel, the excess liquid flowing from the overflow to drain.

- Temperature can be measured at the following 5 locations:

– Vessel contents (cold fluid)

– Hot fluid inlet to jacket/coil

– Hot fluid outlet from jacket/coil

– Cold water outlet to drain

– Cold fluid inlet to vessel

- Quick release hot and cold fluid connections enable rapid connection to HT30X and conversion from heating jacket to heating coil.

FEATURES & BENEFITS

- Miniature jacketed vessel heat exchanger system for use with an Computer Controlled Armfield Heat Exchanger Service Unit

- Comprises processing vessel with outer jacket, inner coil, variable speed stirrer and baffle

- Thermocouples measure the vessel contents and the inlet and outlet temperatures of both fluid streams (5 in total)

- The Heat Exchanger is designed to be installed on the service unit without the need for tools

- A comprehensive instruction manual is included

More.