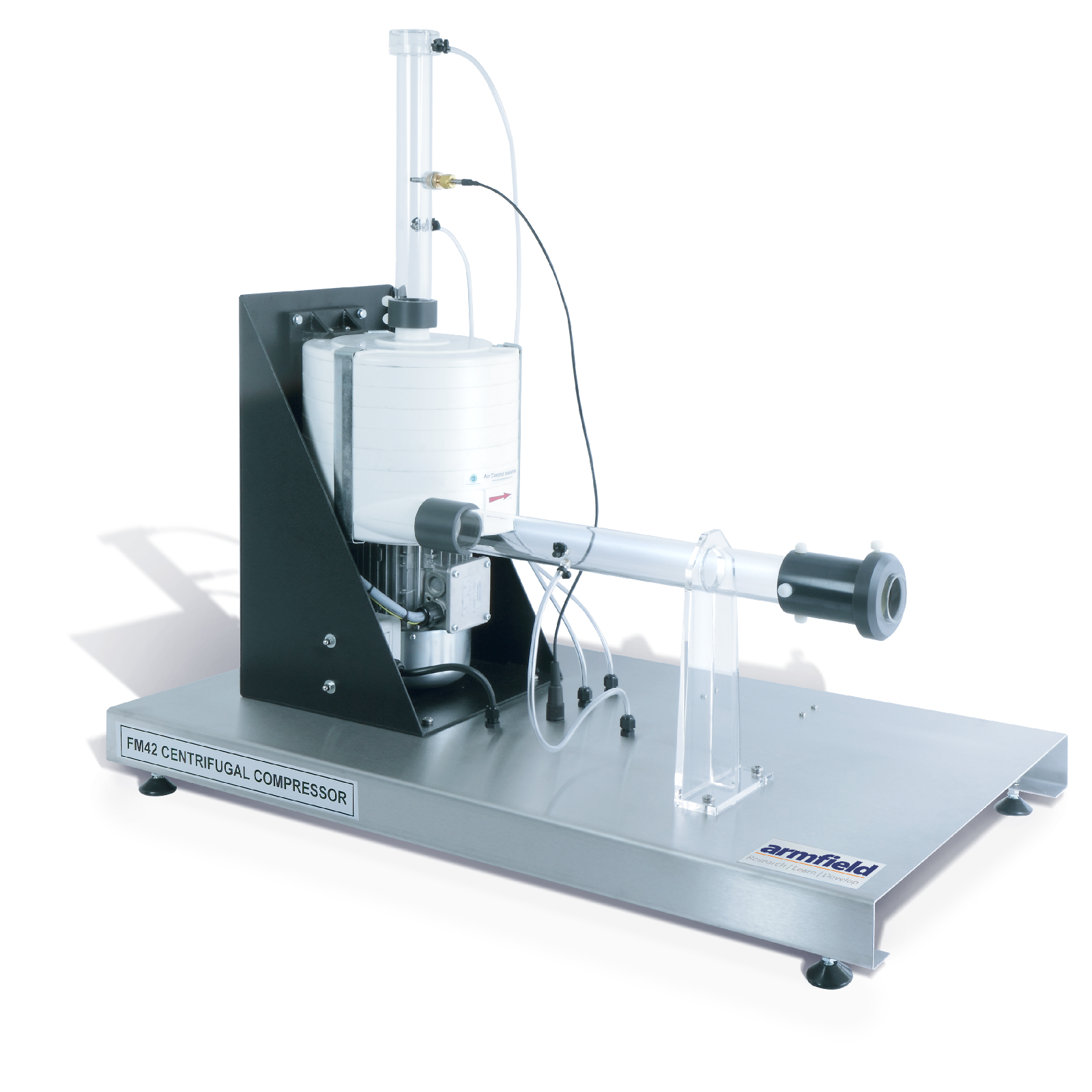

Centrifugal Compressor Demonstration Unit

02 มิถุนายน 2566

ผู้ชม 474 ผู้ชม

DESCRIPTION

A motor driven multi-stage centrifugal compressor mounted on a stainless steel plinth with transparent air inlet and air outlet ducts. A manually operated adjustable aperture allows the air flow rate to be varied at constant fan speed. A calibrated orifice plate is used on the discharge to measure the air flow rate.

Electronic sensors measure the pressure head developed across the blower, the pressure across the orifice plate (and hence the flow rate) and the air temperature.

The compressor speed is accurately controlled by an advanced electronic inverter within the IFD7 (an essential accessory). This inverter also calculates the torque produced at the motor drive shaft allowing the power used by the fan to be derived. The IFD7 also provides the conditioning electronics for the sensors and allows their readings to be displayed on the computer software.

Multi-stage compressors are used industrially for high pressure deliveries of gas flows or suction duties.

The kinetic energy imparted to the gas by the impeller rotation is converted into pressure energy which progressively increases from stage to stage.

DEMONSTRATION CAPABILITIES

- Measurement of constant speed machine performance in terms of static and total pressures, rotor speed and motor shaft power, as a function of inlet flow

- Measurement of compressor efficiency and estimation of impeller power efficiency

- Measurement of performance at constant speeds

- Introduction to similarity laws for scale-up

- Comparison of student calculations with computer results

TECHNICAL SPECIFICATIONS

Max flow rate: 20 l/s typical

Max head: 6.0kPa

Max fan speed: 3,000rpm

Motor power rating: 250W

Number of stages: 7

Pressure sensor: 0 to 12.5mBar