Axial Flow Gas Turbine

29 พฤษภาคม 2566

ผู้ชม 637 ผู้ชม

DESCRIPTION

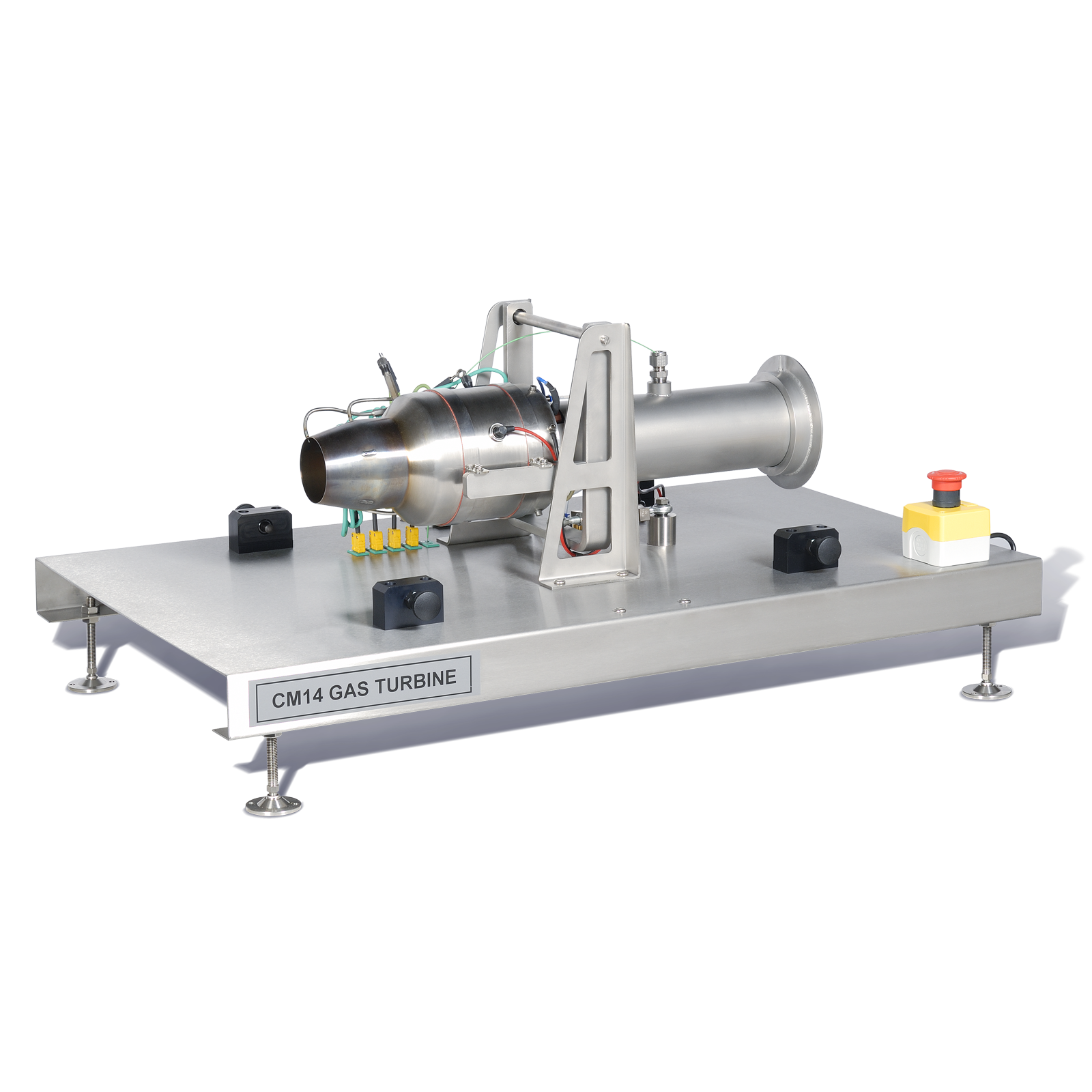

The CM14 axial flow turbine engine, has been integrated into a sturdy metal frame that holds it firmly, while enabling accurate measurement of the thrust produced by the engine.

Electronic preprogrammed controller constantly supervises the engine, ensuring safe operating conditions at all times.

The engine is controlled via the software, which provides users with a graphical interface for real-time monitoring and operation.

The engine is the compact Olympus HP E-start turbine engine, comprising a single-stage radial compressor, an annular combustion chamber and a low-mass, high-performance axial flow turbine.

The engine has been integrated into a sturdy metal frame that holds it firmly, while enabling accurate measurement of the thrust produced by the engine.

The engine inlet has been replaced with a custom fabricated frontal duct, to enable the air mass flow rate to be accurately measured.

An electronic preprogrammed controller constantly supervises the engine, ensuring safe operating conditions at all times.

The engine is controlled via the software, which provides users with a friendly graphical interface for real-time monitoring and operation.

This software controls the engine speed, which is electronically controlled using a high-precision fuel gear pump. This method gives a very fast engine response.

The engine is easy to start and stop from the software interface and automatic, optimal start-up and power-down sequences are already set to assure minimum mechanical stresses. There is no requirement for compressed air supply or propane gas to start the engine.

A tough, transparent polycarbonate screen is fitted in order to make the apparatus completely safe but still provides excellent visibility of the engine when in use. The screen is removable, enabling full access to the engine and instrumentation.

The engine software runs on a personal computer, requiring only a single USB interface between the electronic console and the PC. This enables simple installation into a test cell or soundproof enclosure.

TECHNICAL SPECIFICATIONS

PERFORMANCE SPECIFICATION

- Typical fuel: One of the following choices

- – Paraffin

- – Jet A-1

- – JP-4/Kerosene

- Exhaust gas temperature: 800°C typical

- Mass flow: 450 g/s

- Ignition system: Glow plug

- Compressor type: Single-stage radial

- Turbine type: Single-stage, low-mass axial flow

- Engine rpm: 105,000rpm typical

- Engine mount: Single pivot point

EPERIMENTAL CONTENT

- To estimate the thrust output from the engine, using the momentum equation, and to compare this result to the measured thrust

- To estimate the actual thermodynamic cycle experienced by the flow throughout the engine and represent it in the form of the Temperature vs. Specific Entropy diagram

- To calculate efficiencies of each stage of the engine and the back work ratio