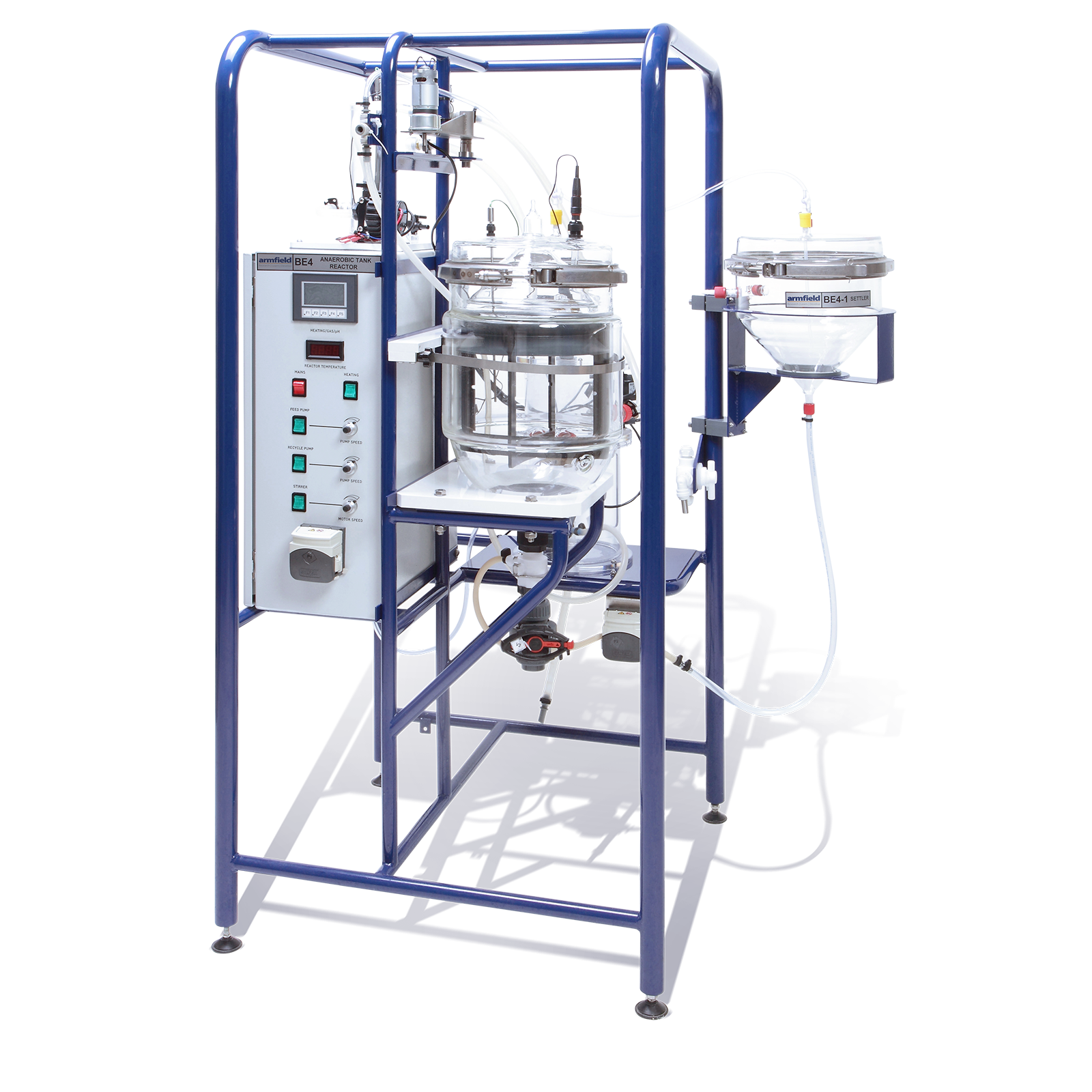

Anaerobic Tank Reactor

26 พฤษภาคม 2566

ผู้ชม 253 ผู้ชม

DESCRIPTION

The reactor on the BE4 is a cylindrical glass vessel with a water jacket for heating. The vessel is supplied with baffles and a variable-speed stirrer for use as a continuous stirred tank reactor (CSTR).

Multi configurable and extremely versatile for both educational and research purposes.

It has a self-contained, floor-standing anaerobic tank reactor of 20 litre volume. The stirrer, motor and baffles are removable for non-stirred configurations.

The reactor on the BE4 is a cylindrical glass vessel with a water jacket for heating. The vessel is supplied with baffles and a variable speed stirrer for use as a continuous stirred tank reactor (CSTR).

The baffles and stirrer are removable to enable the reactor to be filled with bio-balls and a support grill, to reconfigure the unit as a packed bed reactor.

An alternative reactor lid complete with deflector and tri-phase separator is also supplied. This enables the reactor to also be configured as an upflow anaerobic sludge blanket reactor (UASB).

The feed into the reactor is provided by a variable-speed peristaltic pump. The lid of the reactor is fitted with a sampling station, which includes ports for instrumentation probes (both temperature and pH) and permits liquid samples to be taken from the reactor at different depths.

The reactor temperature is controlled by a recirculating water system in the same way as the BE3 and the same novel system for collecting and measuring the emitted gas is used. Similarly the pH dosing system is identical in concept and the data can be recorded on a PC using the data logger.

.jpg)

TECHNICAL SPECIFICATIONS

Reactor volume: 20l

Heater power: 2kW

Jacket temperature: < 60°C

Flow rate (Recycle): 55 l/min

Feed flow rate: 0.06 to 4.81 l/hr

Settler volume: 11l (BE4-1)

FEATURES & BENEFITS

- Continuous stirred tank reactor (CSTR)

- Packed bed reactor (PBR)

- Upflow anaerobic sludge blanket reactor (UASB)

- Measures reactor temperature, jacket temperature and vessel pH

- Programmable logic controller (PLC) provides temperature control, pH control and gas collection (rate and totalisation) calculations

- Jacket heating system with pump and hot water vessel. Temperature is PID controlled room temperature to 55°C

- Automated volumetric gas collection system measures, which adds less than 10 mbar back pressure to the reactor

- Complete with automated pH dosing system to maintain the vessel pH within a predetermined range (user programmable)

- User calibration of pH and gas collection system

- Feed flow rates from 0.06-4.8 l/hr (using interchangeable peristaltic hoses)

- Gas sample point

- Data logger and software as standard (requires PC, not supplied)