Automated Sample Preparation Solution

31 กรกฎาคม 2565

ผู้ชม 414 ผู้ชม

Summary

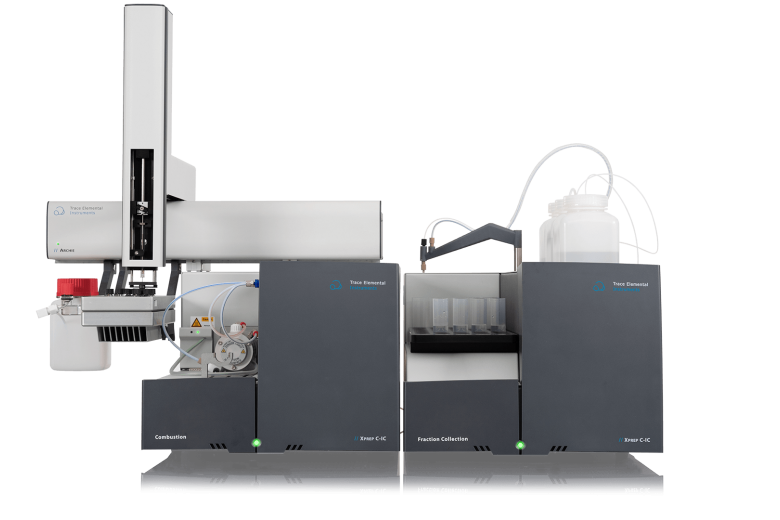

TE Instruments introduces the world’s first independent sample preparation system for Combustion Ion Chromatography analysis: the Xprep C-IC. This unique configuration redefines automated combustion IC analysis through its innovative design and functionalities.

Besides full control over sample combustion, the Xprep C-IC not only collects the oxidized gas stream, but also automatically transfers a fraction of the absorbance solution to any renowned IC system. The ideal solution to cover the increasing demand for analysis of corrosive halogens (Fluor, Chlorine, Bromine, Iodine) and Sulfur compounds (e.g. Sulfate, Sulfite, Thiosulfate) in different matrices. These analytes need to be monitored because they are corrosive, poison catalysts, damage industrial equipment, and are harmful to the environment.

TE Instruments developed a fully automated, extremely compact sample preparation system covering the oxidative pyrohydrolytic combustion, fraction collection, and sample injection towards the IC. The Xprep C-IC can introduce samples both via optimized direct injection (liquids module) and conventional boat-inlet (boat module) into a horizontal furnace. This automated sample-prep solution reduces complexity of sample transfer and significantly improves user convenience.

Key Features Xprep C-IC:

65 position Fraction Collection Unit

• Accurate and repeatable absorbent dosing

• Immediate analysis or storage of combusted samples

• 65 sample positions, eliminates rinsing between samples

Speciated Halides and Sulfur analysis by any renowned IC

• Accurate injection of combusted sample into any renowned IC

Small Footprint

• Half the size compared to existing C-IC configurations

Integrated Sampling System – Fraction Collector

• Fully controls dosing of reagents and absorption of samples

Automated Sample Introduction – Combustion Unit

• Robust sampling systems for all matrices

Oxidative Pyrohydrolitic Combustion of solids, liquids, gas and LPG

• Robust furnace

• Specially developed combustion tube

• Powerful combustion capacity

Application

- Petrochemicals

- (Bio)Fuels

- LPG & Gas

- Lubricants

- Organic Solvents & Chemicals

- Polymers (raw materials and final products)

- Environmental Monitoring (e.g. PFAS Monitoring)

- Electronic Components (e.g. RoHS compliance)

Specification

| Sample introduction | Liquid, Gas & LPG samples by heated liquids introduction module (direct injection) Solid and Liquid samples by quartz boat introduction module (boat-inlet) |

| Compliance | Compliant with the performance standards of international test methods like ASTM, UOP, ISO, DIN, EN, JIS, KS. |

| Sample Types | Solid, Liquid, Gas, LPG |

| Typical Sample Amount | 10 - 250 mg (solids), 5 - 250 µL (liquids), 10 – 250 mL (gas), 100 - 500 µL (LPG) |

| Sample pyrolysis | XPREP C-IC Combustion Tube |

| Furnace voltag | Dual zone, low voltage |

| Furnace temp. | Max. 1150 ℃, 2100 ℉ |

| Gases | Oxygen 99.6% (2.6), Argon 99.99% (4.0) or Helium 99.99% (4.0) |

| Input gas pressure | 3-10 bar (45-150 psi) |

| Absorbent tube | 23 mL - 65 positions (optional 40 mL) |

| Injection to IC | Variable, default 100 µL |

| Flow path material | PTFE, PEEK |

| Remote control | Configurable Remote Start/Stop |

| Voltage | 100 - 240 VAC, 50 - 60 Hz |

| Software | TEIS Software |