หน่วยการกลั่นแยกสาร (Distillation Columns)

28 มีนาคม 2566

ผู้ชม 638 ผู้ชม

SUMMARY.

Armfield has acknowledged these recent changes and has developed two state-of-the-art laboratory-based distillation columns which enable safe hands-on practical training for student engineers and plant operators as well as empowering research in different fields to be conducted.

Armfield has designed two distillation column options:

UOP3BM: Batch Distillation Column (Manual): A Batch-only operated version, manually controlled, which permits a comprehensive study of the basic principles involved in the distillation process.

UOP3CC: UOP3CC – Continuous Distillation Column (Computer Controlled): A Continuous or Batch operated version, computer-controlled, which enables a full range of demonstrations from the introductory stages of a process engineering course through to the more complex demonstrations of modern control strategies.

Each option comes with two different distillation columns supplied:

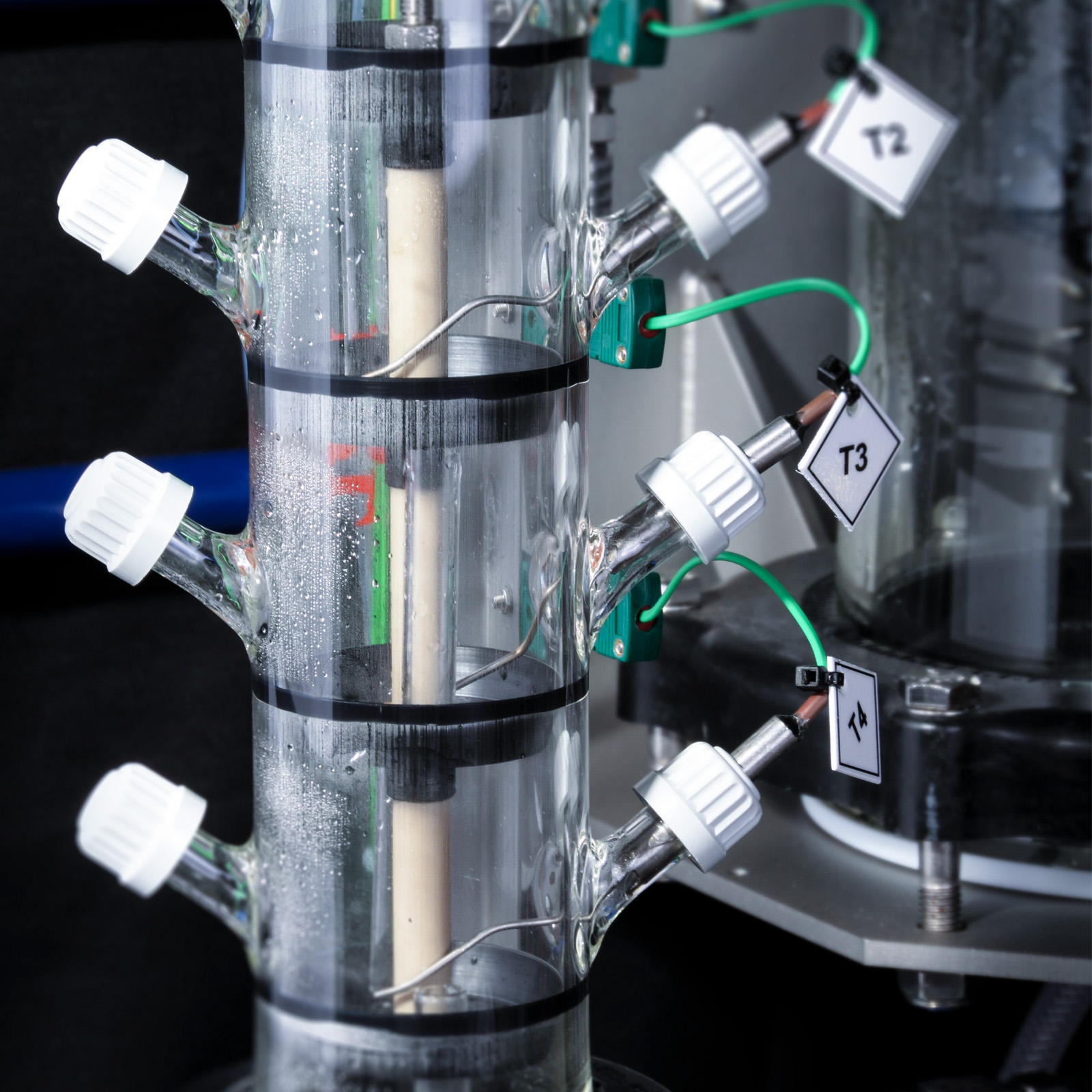

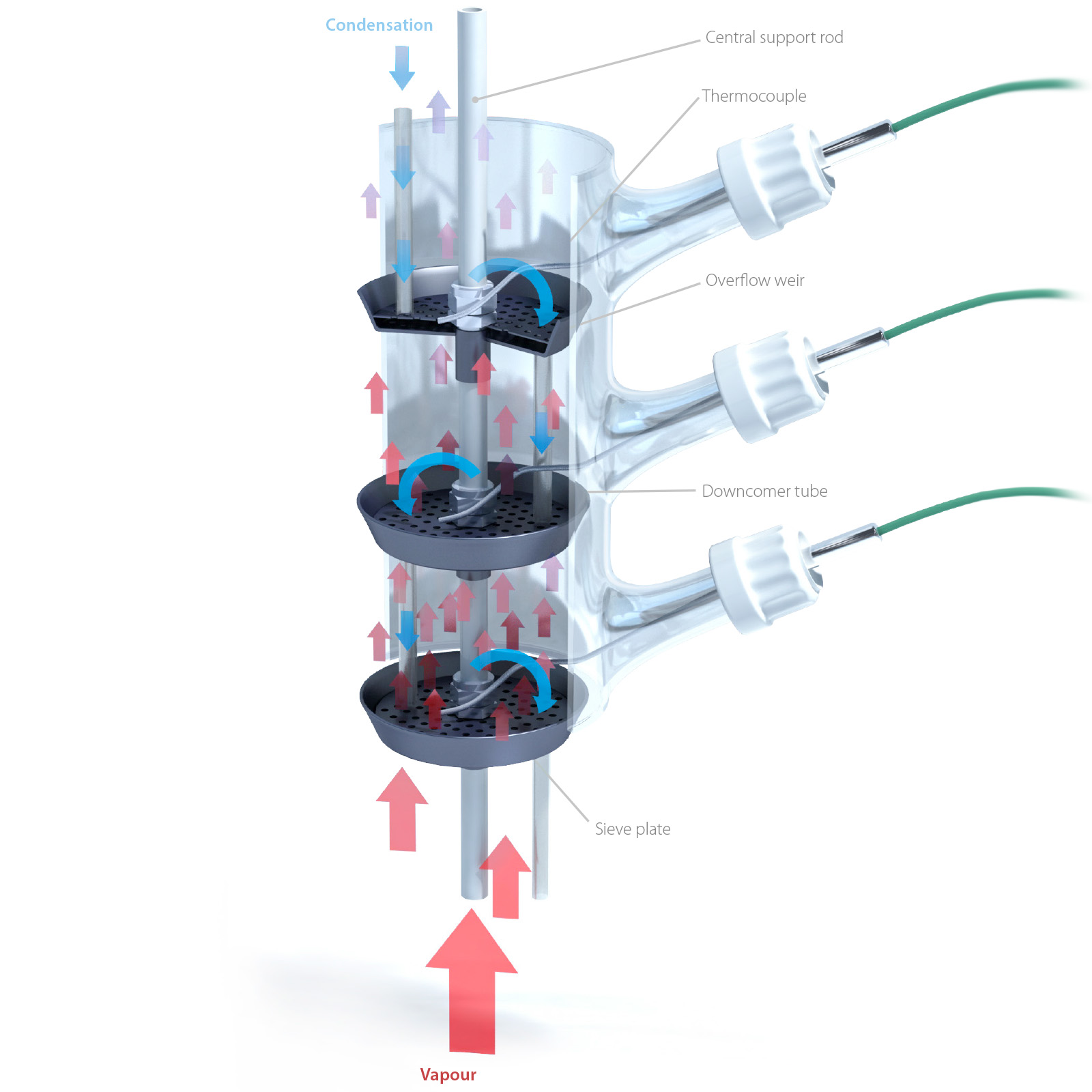

A packed bed distillation column

A sieve plate distillation column, including eight sample and feed ports across the column

Armfield UOP3CC and UOP3BM are the only units on the market with this sampling capability. The column is unique because it can use flammable solvents. In addition, sample ports can be utilised as additional feed positions on each sieve plate. Correct at time of product release.

The unit is a self-contained and fully instrumented distillation facility, suitable for practical laboratory work relevant to the teaching of unit operations.

The equipment employs galvanically isolated intrinsically safe circuits and flameproof devices as appropriate to enable safe distillation of standard test mixtures such as methylcyclohexane-toluene, methyl alcohol-water etc.

The equipment consists of two interconnected units: a floor standing process unit and a bench-mounted control console.

The system includes two distillation columns supplied as standard:

A 50mm diameter plate distillation column containing eight sieve plates and downcomers. Every plate includes a temperature sensor positioned to measure accurately the temperature of the liquid on each plate. The sheaths of each plate temperature sensor are not more than 1.5mm diameter to ensure rapid dynamic response.

A 50mm packed column supplied as a separate item but readily interchangeable with the plate column by the user, for comparative studies of the two types of distillation column.

FEATURES.

- Unique eight-point sample and feed sieve and plate column.

- Eight temperature measuring points along the column’s height.

- Reboiler, Condenser and Reflux tank designed to operate using flammable solvents.

- The vacuum system enables operation at reduced pressures down to 200mbar.

- Interface console enabling local control of the system (also via Software in the UOP3CC version).

- The console front panel presents all the necessary connections to control the unit using any industry-standard PID and/or PLC controllers (not supplied).

- Reflux control ratio from 0 to 100%.

- A U-tube manometer is incorporated to measure pressure drop over the distillation column.

- Supplied fully assembled including lagging and a comprehensive instruction manual.

Features common to both UOP3BM & UOP3CC.

- Electrically heated reboiler with sufficient capacity for up to two hours of batch operation. The reboiler heater is protected against overheating and by a low level alarm.

- Overhead condenser with cooling water flow measurement and adjustment.

- Condensate collecting vessel equipped with double overflow weirs and exit pipes to enable the separation of immiscible liquids.

- A solenoid-operated reflux return valve to provide for 0%-100% reflux, adjustable by the electrical signal.

- Sampling points throughout the system for composition analyses

- The differential manometer is connected to the top and bottom of the column to monitor column pressure drop.

- Vacuum system with a gauge to enable distillation studies at reduced pressures down to 200mbar.

- Materials of construction for surfaces in contact with the process fluids are; glass, stainless steel, PTFE or similar solvent-resistant materials.

- Maximum operating temperature inside the column operation is at least 130 ˚C.

- Temperatures are monitored via fourteen thermocouple sensors located at strategic positions in the system.

Features specific to UOP3CC.

- Two 5 liter feed vessels with the rapid changeover to permit step changes in feed composition to be made.

- Peristaltic feed pump, range 0-0.25 liters/minute adjustable by voltage input variation to the pump motor controller.

- The bottom product heat exchanger which may be either water-cooled or used as a (variable) feed pre-heater.

- The dosing feed vessel is connected to the column for the continuous addition of a third liquid component which, together with the condensate phase separator vessel enables the study of azeotropic distillation.

Control console features common to both UOP3BM & UOP3CC

- Monitoring and selectable display of at least 13 system temperatures including those of the liquid on each tray,

the reboiler and across the condenser. - Monitoring, display and manual adjustment of:

i) the electrical power to the reboiler heater.

ii) the reflux ratio setting. - Mains power connection protected by Residual Current Device.

- Individual circuits are protected against the excess current with resettable circuit breakers.

- Front panel connections to enable the user to connect 0-5 Volt industry-standard analog or programmable logic controllers to provide online control of the boil-up rate or reflux ratio from chosen column temperature measurements.

- The connection points also permit the use of standard laboratory chart recorders and data loggers. (Up to two temperature measurements simultaneously).

Control console features specific to UOP3CC.

- Monitoring, display and manual adjustment of:

i) the electrical power to the reboiler heater (also UOP3BM)

ii) the reflux ratio setting (also UOP3BM)

iii) the feed rate setting - USB connector at the rear of the unit allows connection to a user supplied PC, via the integral USB interface.

- Remote/manual switch is provided on the front panel of the console to enable simple changeover from PC to front panel control to be made by the operator.

- Power and motor control circuits shut down automatically with loss of computer control signals.

Experimental Capabilities - Laboratory exercises common to both UOP3BM & UOP3CC.

- Pressure drop across the column as a function of boil-up rate.

- Column efficiency as a function of boil-up rate at total reflux plate-to-plate temperature profiles along the column.

- McCabe-Thiele construction of operating line.

- Distillation at constant reflux ratio: variation of top product composition with time.

- Mass balance across the system.

- Manual control of reflux ratio; for example to achieve a top product of a specified composition.

- Comparison of packed column with sieve plate column performance.

Experimental Capabilities - Laboratory exercises specific to UOP3CC

- Continuous steady-state distillation including temperature profiles and McCabe-Thiele analysis.

- Effect of feed pre-heat.

- Effect of feed position.

- Demonstration of azeotropic distillation.

- Using a PID Controller (requires additional non-supplied equipment).

- Using a PLC Controller (requires additional non-supplied equipment).